Baucor's End-to-End Solutions: From Concept to Delivery

Baucor is a renowned company in the cutting tool industry, known for its innovation, precision, and commitment to delivering high-quality products. With years of experience, Baucor has established itself as a leading player in the market.

When it comes to manufacturing and delivering cutting tools, end-to-end solutions are crucial. Baucor handles every aspect of the process, from conceptualization to final delivery. By having complete control over each step, Baucor ensures that its customers receive top-notch products that meet their specific requirements.

Starting with ideation and concept development, Baucor works closely with clients to understand their unique needs and challenges. From there, highly skilled engineers translate these concepts into detailed designs using advanced CAD software.

The purpose of this document was to shed light on Baucor's comprehensive process from concept development through production and delivery – highlighting how they consistently deliver superior results for their customers.

In an ever-evolving manufacturing landscape, comprehensive solutions are essential for success. And when it comes to cutting tool production, Baucor leaves no stone unturned. Let's explore how Baucor's state-of-the-art approach revolutionizes how cutting tools are manufactured and delivered.

Conceptualization and Design

Initial Consultation

At Baucor, conceptualization and design are essential steps toward their state-of-the-art solutions. They start by having a thorough knowledge of their customer's needs and expectations through an initial consultation. It enables them to adjust their strategy to their particular circumstance precisely.

In the consultation stage, Baucor spent time paying close attention and posing pertinent queries. By doing this, they ensure that all project information is noticed and considered. Their questions include what and how to cut.

Baucor evaluates the current application after they have a firm grasp of the customer's vision. It entails looking at things like the characteristics of the material, its thickness, its degree of hardness, and the precise tolerances needed for precision cutting.

In addition, they employ cutting-edge instruments and methods to perform an extensive analysis of the material. Knowing what makes it up allows them to determine the best ways to get precise cuts without sacrificing effectiveness or quality.

Their team of professionals uses state-of-the-art technology and years of experience to create creative solutions that are customized to meet the demands of each customer. When it comes to concept creation, design refinement, and manufacturing, Baucor makes sure that every detail is carefully taken care of.

Design and Prototyping

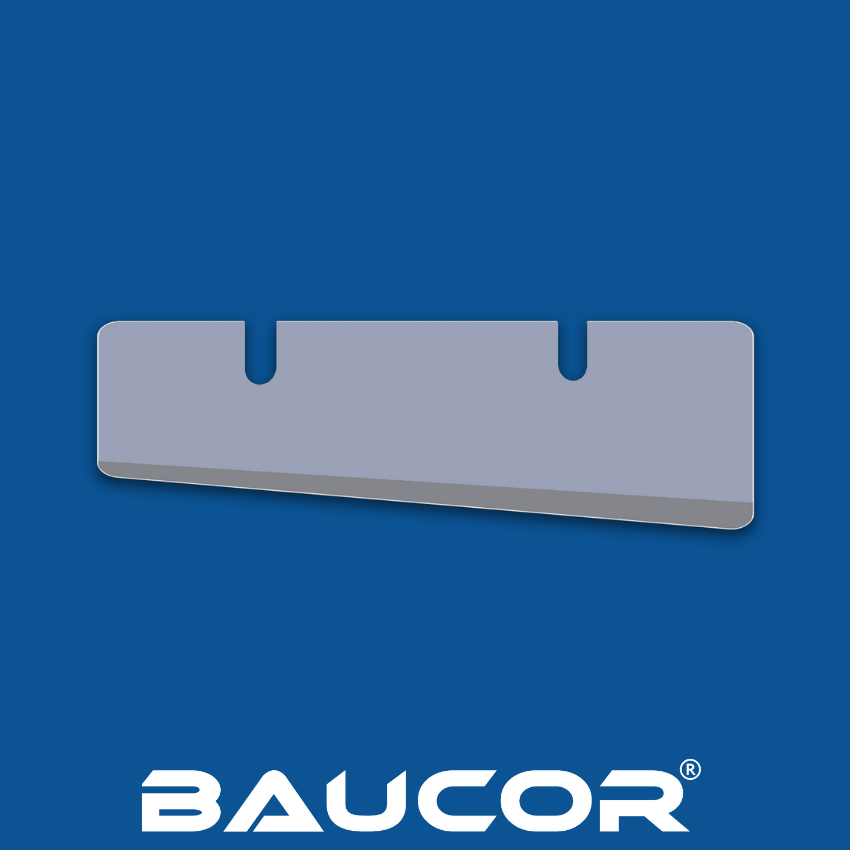

When it comes to producing cutting tools of the highest caliber, Baucor is proud of the involvement of its knowledgeable design team. These experts possess years of expertise and a thorough comprehension of the minute intricacies of creating precision cutting blades.

Baucor uses cutting-edge CAD/CAM technology to ensure that every blade part gets designed. Precise modeling and virtual testing before an actual prototype is made possible by this program. Using this technology, Baucor can spot potential problems early in the design phase and make the required corrections.

Another benefit of using CAD/CAM technology is that Baucor can produce prototypes rapidly and effectively. Modern equipment creates actual prototypes from digital blueprints with precise measurements.

When prototypes are ready, intensive testing begins. They test every blade to ensure it meets performance criteria. Necessary modifications originate to achieve the best results.Through their experience with CAD/CAM technology and knowledge of blade design, Baucor ensures that their cutting tools meet or surpass customer expectations. They aim for quality at every level of the production process, from conception to delivery.

Prototype Development and Testing

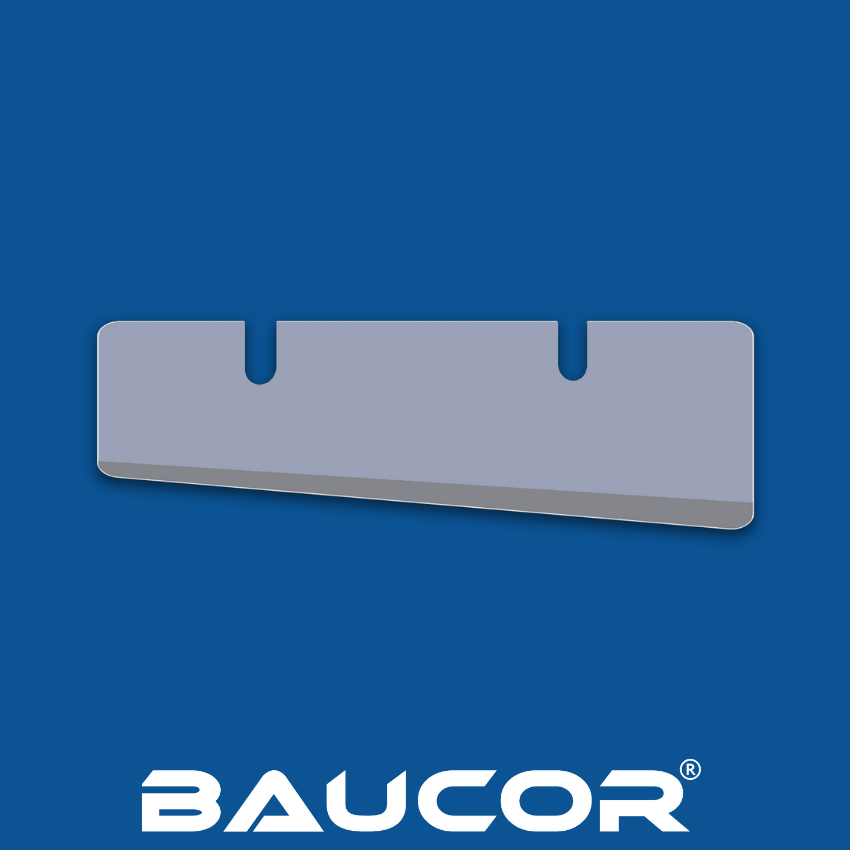

After the design is complete, Baucor's team develops a prototype to make the final version of the idea a reality. Before beginning production, this vital phase enables us to evaluate the cutting instruments' performance and usefulness.

Their skilled workers meticulously build each prototype using modern production tools and methods. To ensure an exact picture of the finished product, they use cutting-edge materials that closely mimic those utilized in actual manufacturing runs.

Thorough testing parallels creating prototypes to assess attributes, including accuracy, efficiency, and durability. Every tool is put through its paces by its committed quality assurance team, which subjects it to various real-world scenarios to find potential problems or areas that could use improvement.

Before starting mass production, they may make any necessary improvements or tweaks thanks to this detailed process of prototyping and testing. It enables us to provide cutting tools that, in terms of longevity and performance, match and surpass client expectations.

GET A QUOTE

Material Selection and Procurement

Selection of High-Quality Materials

Material selection is a crucial part of any manufacturing process. At Baucor, they recognize how vital it is to select premium materials that are ideal for the task at hand. Using their experience and understanding, they carefully consider several material possibilities to guarantee the best possible performance and longevity.

There are several things to consider when it comes to material attributes. For example, a blade's ability to tolerate abrasion depends on its hardness. Longevity ensures without sacrificing flexibility when hardness and toughness are correctly balanced.

The ability to withstand corrosion is another crucial feature. Certain materials may be more prone to corrosion than others, depending on the application. They can ensure extended tool life and low maintenance costs by choosing materials with superior corrosion resistance properties.

Furthermore, in high-temperature applications, heat resistance is essential. Superior heat resistance allows materials to withstand high temperatures without degrading or distorting, guaranteeing reliable performance even in the most adverse circumstances. Their cost-effectiveness is maintained as they obtain dependable sources for premium materials thanks to their alliances with responsible suppliers.

Quality Assurance

At Baucor, they understand this and prioritize quality assurance throughout every step of their process. Their dedication to quality is what makes them stand out from the competitors.

Baucors customers are guaranteed to receive only items that exceed the highest standards thanks to their comprehensive quality control systems. They have established an extensive system that monitors and inspects every step of the production process, from the selection of raw materials to the last delivery. They do not allow an opportunity for error or compromise because devoted professionals oversee these procedures.

A vital part of their efforts to ensure quality is material testing. All materials pass through extensive testing to guarantee their integrity and performance qualities before production. It assesses elements, including corrosion resistance, tensile strength, durability, and hardness. They are confident in their abilities to attest to the dependability of their products since they routinely conduct these tests and keep accurate records of the outcomes.

Additionally, certification is essential to confirming the caliber of their services. Baucor is pleased to possess several certificates that verify its compliance with global norms for safe product handling and production procedures. These accreditations testify to their dedication to quality and give their esteemed clients—who depend on them for their cutting-edge solutions—peace of mind.

Baucor's knowledge and commitment to quality and precision allow them to provide custom-made precision tools and blades.

Precision Manufacturing

State-of-the-Art Manufacturing Facilities

Precision manufacturing requires the perfect blend of cutting-edge technology and human expertise. At Baucor, they take great pleasure in having advanced manufacturing facilities that can handle even the most exacting production specifications.

Baucor can attain previously unheard-of levels of accuracy and precision thanks to the state-of-the-art machinery and equipment housed in their facilities. Every tool in their toolbox, from CNC machines to EDM wire-cutting equipment, has been meticulously chosen to guarantee peak performance and faultless outcomes.

However, more than having excellent equipment is needed; you also need a staff with the know-how to utilize the equipment thoroughly. The company staff comprises skilled professionals, engineers, and artisans who are enthusiastic about their work. Their vast expertise and experience enable them to effortlessly handle intricate production procedures, guaranteeing that every product fulfills the most exacting quality requirements.

An essential component of precise production is engineering expertise. From idea creation to design optimization, the committed engineering team works directly with clients, offering insightful advice and recommendations at every step.

Manufacturing Processes

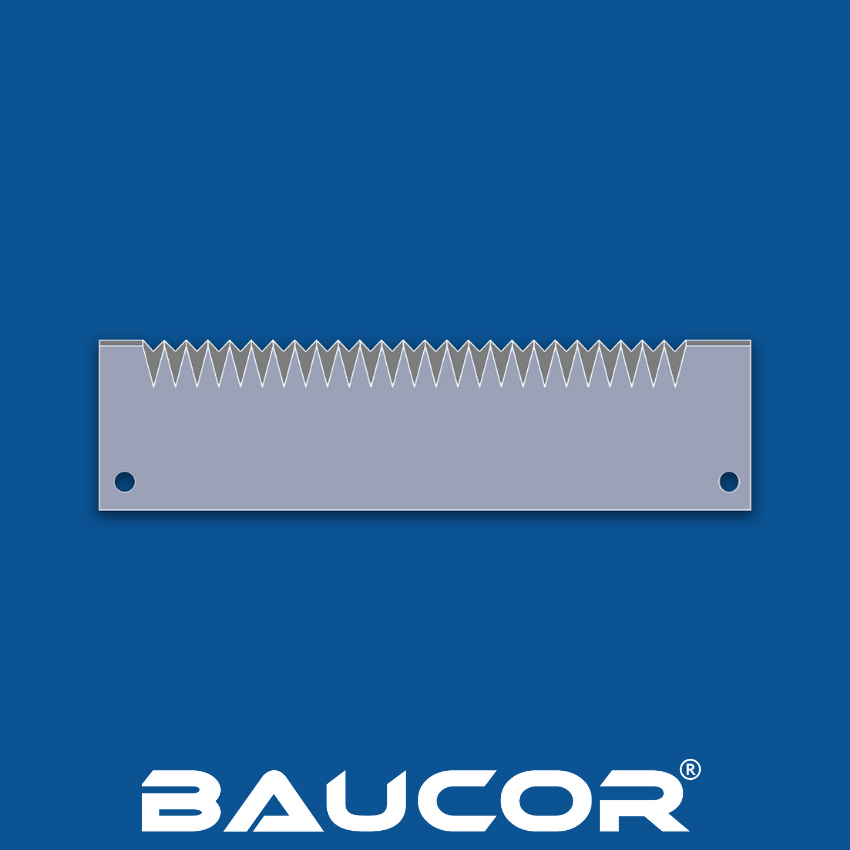

Precision and accuracy are the cornerstones of Baucor's manufacturing processes for cutting tools. Every stage is carefully carried out from beginning to end to provide the best possible products.

The procedure starts with thoroughly examining the needs and specifications provided by the client. It requires choosing the material to get cut, which has the necessary measurements and tolerances. Equipped with this data, the engineering team at Baucor creates a tailored strategy for tool manufacturing.

The selection of materials is the next step. There is only premium steel used, which has been hand-picked for lifespan and durability. The materials undergo rigorous testing to guarantee they are suitable for cutting applications.

After the materials are accepted, sophisticated machinery such as wire EDM (Electrical Discharge Machining) equipment and CNC grinding machines shape the materials into the desired shapes precisely. These cutting-edge devices enable precise sculpting, guaranteeing that every detail is as specified.

Each tool passes a rigorous examination procedure after shaping to ensure accuracy and precision. It covers visual inspections by qualified technicians and dimensional examinations with calibrated measuring devices.

Upon examination, any discrepancies or flaws get corrected right away. Baucor is proud to offer its clients only perfect products, whether it's correcting surface defects or fine-tuning dimensions.

At Baucor, meticulous attention to detail is critical at every production level. Their dedication to precision production guarantees that every cutting tool meets or beyond customer requirements from design to delivery.

Quality Control

Quality control is a cornerstone of Baucor's operations, and they leave no stone unturned when it comes to ensuring the highest standards in their products. Quality inspections carried out during the process are one method they accomplish this. Their skilled team performs thorough inspections at different manufacturing phases to find anomalies or potential problems.

These inspections use cutting-edge techniques and methodologies to identify potential issues before they grow. By doing this, Baucor can take care of them immediately and keep them from affecting the finished product. Every detail is meticulously examined, from using precise devices to measure dimensions to visually inspecting items for defects or imperfections.

However, they are fully committed to ensuring the quality of the finished product, even at that point. The company items must go through extensive testing and review at this point before they can be shipped. Their committed quality control staff painstakingly inspects every item to ensure that it meets stringent standards for performance, durability, and functionality.

They adhere to established procedures based on industry best practices to guarantee consistency and accuracy in these evaluations. The company's conscientious professionals inspect every little detail, whether checking industrial blade alignment tolerances or inspecting cutting edges for sharpness.

Baucor's end-to-end solutions ensure your products exceed quality control standards. They take great satisfaction in providing their clients in the packaging and food processing industries with impeccable outcomes that inspire confidence.

Assembly and Testing

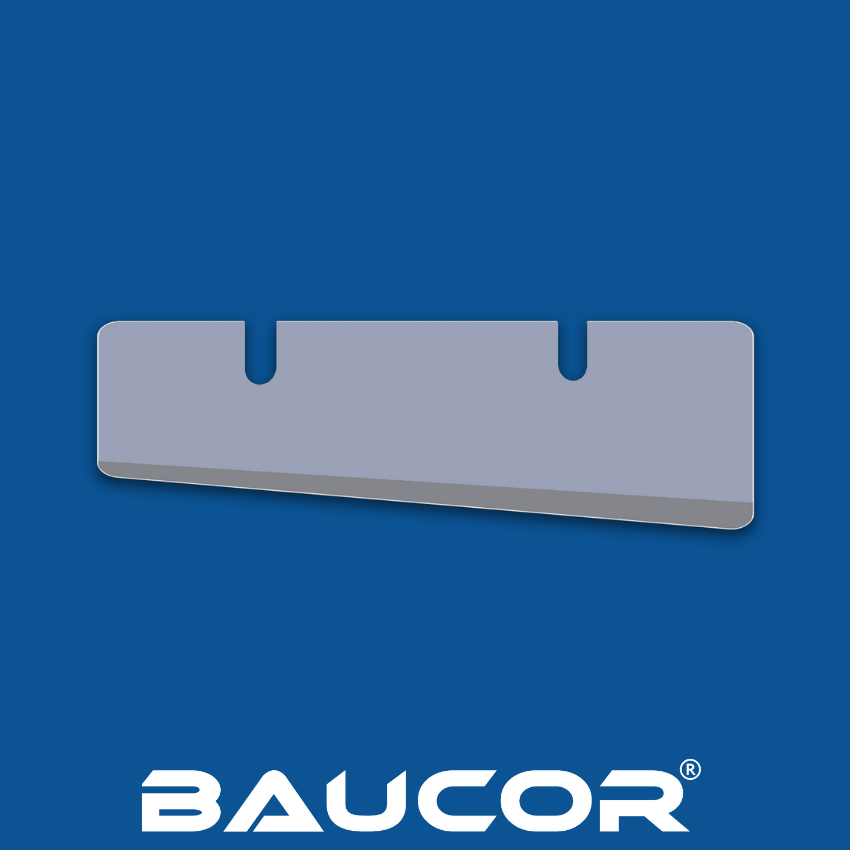

Assembly and testing are the backbone of Baucor's end-to-end solutions, ensuring that every product they deliver meets the highest standards of precision and functionality. Their team of experts uses state-of-the-art methods to ensure perfect assembly.

Precision assembly is at the core of their operations. It guarantees that every component works flawlessly with the others to produce an end product that operates at its best.

Precision assembly goes hand in hand with ensuring alignment and functionality. Their specialists carefully inspect the product for any misalignments or irregularities that can affect its functionality. They ensure that everything functions as planned with careful inspections and modifications.

One crucial step in their methodology is performance testing. To replicate the real-world usage environment of each constructed product, they put it through rigorous testing. It enables us to find any possible problems or flaws before they get into their hands.

An additional crucial component of their assembly and testing cover is the verification of specifications and performance standards. To make sure that the performance meets both client demands and industry standards, they compare the actual performance to predefined parameters.

Packaging and Delivery

Baucor takes excellent care to ensure the safety and security of your products during the packaging and transportation processes. Because they know that an item properly packaged has a higher chance of arriving at its destination undamaged, they go above and beyond in choosing suitable materials for every shipment. To stop damage during transit, their staff uses materials like foam inserts, bubble wrap, and robust packaging. These reliable choices will provide you peace of mind that your items are safe throughout transport.

Baucor provides customized packaging for your products. Their experts will collaborate closely with you to create packing tailored to your specific needs, whether you are transporting heavy industrial components or delicate goods. You will save time and money by doing this, which maximizes space efficiency and assures optimal protection.

Baucor is excellent at safe packaging, but they also does excellent delivery work. Additionally, you don't need to worry about losing track of your shipment because they offer thorough tracking services that let you keep tabs on its advancement at every turn.

If you have any queries or worries about the progress of your order's delivery, their committed customer service team is always there to help you in a timely and courteous manner. To provide their esteemed clients with timely solutions, they recognize the significance of open communication and transparency.

GET A QUOTE

After-Sale Support and Services

Customer Support

At Baucor, they take pride in their dedicated customer service team that is always ready to go above and beyond for their valued clients. Professionals with extensive experience who are enthusiastic about offering the best possible support and help make up their team. You can be confident that their customer support agents will be there to help you at every turn as soon as you contact us with a question or problem.

Their ability to respond quickly to consumer requests and problems is one of their unique selling points. They recognize the value of fast communication and work hard to deliver timely solutions. Regardless of how straightforward the inquiry is or how complicated the issue is, their crew works hard to ensure your demands are effectively satisfied.

You should expect nothing less than the best after-sale services and support when you choose Baucor. Their dedication is there for their relationship with us, not just at the point of sale. Since they consider your satisfaction to be of utmost importance, they make providing exceptional customer service a key component of their business strategy.

Maintenance and Repairs

Any product's longevity and functionality depend heavily on maintenance and repairs. At Baucor, they recognize the value of giving their clients access to dependable maintenance services and premium replacement components.

Their dedication to client pleasure goes beyond the moment of sale. For all of their products, they have a large inventory of spare parts that are easily accessible, guaranteeing less downtime if repairs or replacements are necessary. Whether it's a tool holder, blade, or any other factor, you can rely on us to deliver the appropriate amount quickly.

Their team of skilled experts is well-versed in repair and maintenance services, and they have an extensive inventory of replacement parts. These experts have years of experience using their devices and have the know-how necessary to correctly and quickly detect problems.

They go above and beyond by providing planned inspections and preventive maintenance plans for maintenance services. In addition to resolving current issues, their specialists will look for areas that need attention to avoid more malfunctions or inefficiencies.

Regular maintenance and using original Baucor replacement parts can help you keep your equipment operating at peak performance for its life while reducing unplanned downtime from unanticipated breakdowns.

Continuous Improvement

At Baucor, they think that providing a product is only the beginning of the journey. They're dedicated to enhancing their products constantly using insightful feedback from their clients. They rely heavily on customer feedback to better understand their wants and preferences, an essential element of their approach.

They take the time to listen to the experiences, recommendations, and worries of their clients because they value all viewpoints. They can find opportunities to improve or add new features to enhance their customers' experience with their products by actively interacting with them.

However, their work continues. They don't merely fold their hands and call it a day. Their committed staff makes endless efforts to evaluate the information gathered and convert it into doable actions for advancement. They make continuous investments in product development because they recognize that innovation is essential in the quickly changing world of today.

Their dedication to ongoing development propels us forward in the direction of developing innovative solutions that go above and beyond expectations.

You can be sure that when you work with Baucor, you are working with a firm committed to exceeding your expectations at every stage, from concept conception to delivery. Your happiness is still at the center of all they do, whether by supplying first-rate customer service, maintenance services supported by knowledgeable technicians, or a wholehearted commitment to continuous product development.

Conclusion

As they near the end of their exploration into Baucor's end-to-end solutions, it's clear that their commitment to excellence sets them apart from the competition. Throughout this journey, they've learned about Baucor's wide range of precision cutting tools and their expertise in various industries.

Baucor understands that each project is unique and requires a tailored approach. From the initial concept stage to final delivery, they work closely with clients to ensure every detail.

In closing, Baucor's end-to-end solutions encompass more than just delivering a product; they offer a partnership built on trust, quality, and reliability. Whether you're looking for custom blades or specialized cutting tools, Baucor has the expertise and capabilities to bring your ideas to life. Trust in Baucor as your go-to solution provider for all your cutting tool needs!

English

English