EXPERIENCE THE FUTURE OF TAP TECHNOLOGY WITH BAUCOR:

SEAMLESS SOLUTIONS THAT TRANSFORM THE WAY YOU INTERACT WITH WATER, EVERY DAY

EXPERIENCE THE FUTURE OF TAP TECHNOLOGY WITH BAUCOR:

SEAMLESS SOLUTIONS THAT TRANSFORM THE WAY YOU INTERACT WITH WATER, EVERY DAY

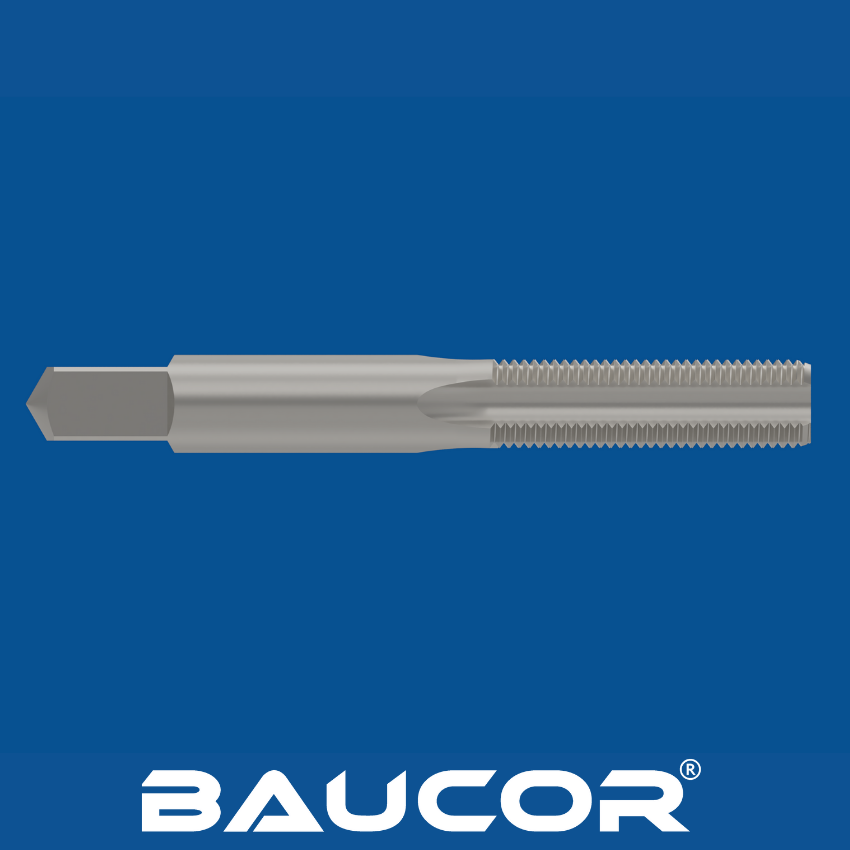

Bottoming Taps: Threading to the Bottom of Blind Holes

Bottoming taps, also known as plug taps, are cutting tools designed for creating threads in blind holes, which are holes that do not go all the way through a workpiece. Their unique design allows them to cut threads to the very bottom of the hole, ensuring a complete and secure thread engagement.

How Bottoming Taps Work

Full Thread Profile: Unlike other taps with tapered leads, bottoming taps have a full thread profile that extends all the way to the tip. This design allows them to cut threads right to the bottom of a blind hole without leaving any unthreaded portion.

Cutting Action: Like other taps, bottoming taps have cutting edges that remove material from the workpiece to form the threads. As the tap is rotated and fed into the hole, the cutting edges gradually cut away material, creating the helical grooves that form the internal threads.

Chip Removal: The flutes between the cutting edges serve to channel chips out of the hole. In blind holes, the chips are collected in the flutes and then removed when the tap is withdrawn.

Bottoming Taps: Threading to the Bottom of Blind Holes

Bottoming taps, also known as plug taps, are cutting tools designed for creating threads in blind holes, which are holes that do not go all the way through a workpiece. Their unique design allows them to cut threads to the very bottom of the hole, ensuring a complete and secure thread engagement.

How Bottoming Taps Work

Benefits of Using Bottoming Taps

Applications of Bottoming Taps

Bottoming taps are used in various industries and applications where blind holes need to be threaded, including:

Manufacturing Process of Bottoming Taps

The manufacturing process for bottoming taps is similar to that of other taps, with a few key differences:

By following this meticulous manufacturing process, high-quality bottoming taps are produced, capable of creating strong and reliable threads in blind holes across various industries and applications.

As a leading manufacturer of cutting tools, Baucor offers a wide range of bottoming tap sizes to cater to the diverse needs of their customers across various industries. While their specific product catalog may vary, you can expect the following size ranges:

Fractional Sizes (Inch):

Oversize: Baucor might also offer oversize bottoming taps for specific applications where a slightly larger thread is desired for improved fit or strength.

Metric Sizes (Millimeter):

Standard: A broad selection of metric sizes, likely starting from M1, M1.2, M1.6, M2, and progressing to larger diameters like M10, M12, M16, or even higher, catering to users who prefer metric measurements.

Specialty Sizes:

Additional Considerations:

Obtaining Precise Information:

To obtain the most accurate and up-to-date information on the specific sizes of bottoming taps manufactured by Baucor, it is recommended to:

By utilizing these resources, you can ensure that you select the perfect Baucor bottoming tap size for your threading applications.

Spiral flute taps are specialized cutting tools designed to create internal threads in pre-drilled holes. They're a popular choice due to their efficient chip removal capabilities, particularly in through-holes.

A spiral point tap, also known as a gun tap, is a type of tap used for cutting threads in a hole. Unlike traditional taps, which may push material forward, a spiral point tap features flutes with a spiral design that effectively pushes chips ahead of the cutting action.

Pipe taps are specialized tools designed to create internal threads in pipes and fittings, allowing for leakproof connections in plumbing, hydraulic, and other fluid-carrying systems.

Thread forming taps offer an alternative to traditional cutting taps. Instead of removing material, they reshape it through a process known as cold forming, creating internal threads in ductile metals.

Bottoming taps, designed to thread the full depth of a blind hole, are made from various materials to suit different applications and workpiece materials. Here's a list of the possible materials used:

Common Materials:

Less Common Materials:

Additional Considerations:

Choosing the right material for a bottoming tap depends on the specific application, the workpiece material, the desired thread quality, and budget considerations. For most general-purpose threading, HSS is a suitable and cost-effective choice. However, for harder materials, high-volume production, or demanding applications, cobalt or carbide taps may be more appropriate. Consulting with a knowledgeable supplier or manufacturer can help you select the best material for your specific needs.

Bottoming taps, designed to thread the full depth of a blind hole, are made from various materials to suit different applications and workpiece materials. Here's a list of the possible materials used:

Common Materials:

Less Common Materials:

Additional Considerations:

Choosing the right material for a bottoming tap depends on the specific application, the workpiece material, the desired thread quality, and budget considerations. For most general-purpose threading, HSS is a suitable and cost-effective choice. However, for harder materials, high-volume production, or demanding applications, cobalt or carbide taps may be more appropriate. Consulting with a knowledgeable supplier or manufacturer can help you select the best material for your specific needs.

Bottoming taps can be enhanced with various coatings to improve their performance, tool life, and versatility. Here are the common and specialized coatings used:

Common Coatings:

Other Coatings:

Choosing the Right Coating:

The ideal coating for a bottoming tap depends on several factors, including:

Consulting with the tap manufacturer or a knowledgeable supplier can help you select the optimal coating for your specific needs.

Bottoming taps are essential tools for creating threads in blind holes, a common requirement across various industries and applications.

Industrial Applications:

Other Applications:

The versatility of bottoming taps makes them indispensable tools in various industries and applications where precise and complete threading of blind holes is required.

Bottoming taps, specialized for threading blind holes to their full depth, are crucial tools in various industries that require precise and secure internal threading. Here's a breakdown of the key industries where bottoming taps are commonly used:

The versatility of bottoming taps makes them indispensable tools in numerous industries and applications where precise and complete threading of blind holes is required.

Bottoming taps, designed to cut threads to the very bottom of a blind hole, are primarily used with machines that provide precise control and stability for threading operations. These machines include:

Choosing the Right Machine:

The choice of machine for bottoming tapping depends on several factors:

By carefully evaluating these factors, you can choose the most suitable machine for your bottoming tapping application, ensuring efficient and accurate thread production.

A straight flute tap, also known as a hand tap, is a common cutting tool used to create internal threads in a pre-drilled hole. They're often used manually but also work in machines like drill presses.

Machine screw taps are specialized tools designed to cut internal threads in pre-drilled holes. These threads are standardized to accept machine screws, providing secure and reliable fastening solutions across a wide range of industries and applications.

Combination machine taps are specialized tools designed to streamline the thread-cutting process by combining multiple operations into a single tap. This makes them particularly useful in production environments where minimizing tool changes and optimizing cycle times are crucial.

Bent Shank Taps are a specialized type of tap designed with a bent or curved shank, distinguishing them from the straight shanks typically seen on most taps. This design is particularly useful for reaching inaccessible or awkward areas where a straight tap cannot be properly aligned or rotated.

As a leading manufacturer of cutting tools, Baucor likely offers a comprehensive range of design and engineering support services for their bottoming taps, aimed at helping customers optimize their tapping processes and achieve the best possible results. These services could include:

Design Support:

Engineering Support:

Additional Services:

By providing a comprehensive suite of design and engineering support services, Baucor aims to be a valuable partner for their customers, helping them achieve the best possible results in their tapping operations.

BAUCOR offers custom manufacturing and engineering solutions tailored to your specific needs, across various industries.

BAUCOR's engineers can review your design and provide feedback to improve manufacturability, cost effectiveness, and efficiency.

Bottoming taps, designed for threading blind holes to their full depth, follow specific design principles to ensure optimal performance and thread quality:

By adhering to these design guides, manufacturers can produce high-quality bottoming taps that deliver reliable and efficient performance in threading blind holes. The precise combination of full thread profile, cutting edge geometry, and material selection ensures optimal thread quality, minimal friction, and reduced risk of tap breakage, making bottoming taps essential for various applications across different industries.