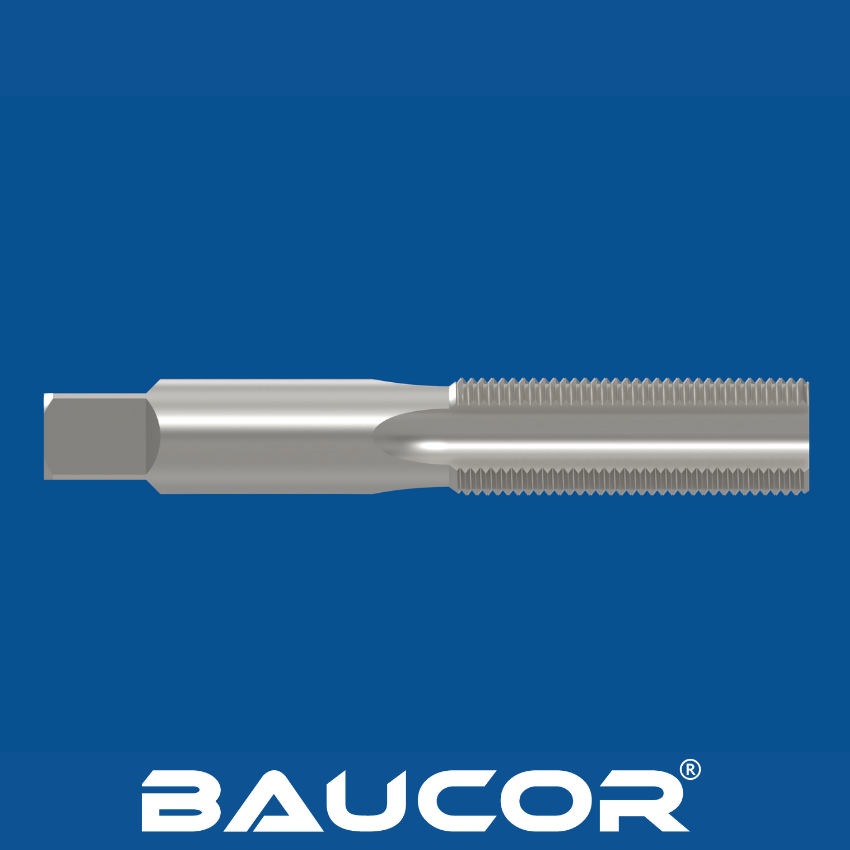

DISCOVER THE BAUCOR LEGACY:

GENERATIONS OF TAP INNOVATION AND A COMMITMENT TO EXCELLENCE.

DISCOVER THE BAUCOR LEGACY:

GENERATIONS OF TAP INNOVATION AND A COMMITMENT TO EXCELLENCE.

Gas thread taps are specialized taps designed to create leakproof, tapered threads primarily used in plumbing, pipefitting, and gas transportation systems. They conform to specific standards to ensure compatibility with standard gas fittings and pipes.

Types of Gas Thread Standards

Some common gas thread standards gas thread taps might adhere to:

How Gas Thread Taps Work

Key Points about Gas Thread Taps

Gas thread taps, with their specialized tapered design and leak-proof thread creation capabilities, require a rigorous manufacturing process to meet the demands of the plumbing and gas industries. Let's explore the key stages:

Material Selection & Preparation:

Blank Forming: The basic tap shape begins to emerge:

Thread Creation: The heart of the process!

Heat Treatment (Final):

Surface Treatments (Optional): Manufacturers may offer coatings for enhanced performance:

Spiral flute taps are specialized cutting tools designed to create internal threads in pre-drilled holes. They're a popular choice due to their efficient chip removal capabilities, particularly in through-holes.

A spiral point tap, also known as a gun tap, is a type of tap used for cutting threads in a hole. Unlike traditional taps, which may push material forward, a spiral point tap features flutes with a spiral design that effectively pushes chips ahead of the cutting action.

Pipe taps are specialized tools designed to create internal threads in pipes and fittings, allowing for leakproof connections in plumbing, hydraulic, and other fluid-carrying systems.

Thread forming taps offer an alternative to traditional cutting taps. Instead of removing material, they reshape it through a process known as cold forming, creating internal threads in ductile metals.

With a commitment to providing quality tooling solutions, Baucor manufactures gas thread taps in a wide variety of sizes to accommodate various gas line components, fittings, and threading standards. Our expertise ensures precision and compatibility with common gas line requirements.

Potential Gas Thread Tap Sizes from Baucor

While specific sizes depend on the thread standards you require, Baucor offers gas thread taps in the most widely used sizes, potentially including:

BSPT (British Standard Pipe Taper)

Other Potential Standards:

Baucor can manufacture taps for you ranging from very small sizes like M0.5 to large sizes up to M68, accommodating a wide spectrum of threading requirements.

Please contact us for the appropriate dimensions. Baucor can produce taps in the most specialized sizes tailored to your needs.

Gas thread taps, designed for forming leak-proof connections in pipes, need to possess the right combination of hardness, toughness, and wear resistance. Here's what manufacturers like Baucor typically use:

Common Materials

Specialty Materials

Carbide: For extremely high wear-resistance and when cutting the toughest of pipe materials, solid carbide gas thread taps might be an option, primarily in high-volume production scenarios. However, these are the most expensive and tend to be more brittle than HSS options.

Specialty Tool Steels: In niche applications, some manufacturers might utilize high-performance tool steel grades. These might have property blends tailored to very specific challenges, but would likely come with an even higher cost.

Surface Treatments and Coatings: Beyond the base material, coatings play a significant role:

Choosing the Right Material: Factors to Consider

Collaborating with a company like Baucor can help you select the perfect tap material based on:

Choosing the right coating can have a significant impact on the performance and longevity of your gas thread taps. Baucor, focused on quality, likely offers a range of coatings to help you optimize your operations:

Common Coatings

Titanium Nitride (TiN): The classic gold-colored coating offering a versatile upgrade:

Titanium Aluminum Nitride (TiAlN): Ideal for higher temperatures and tougher materials:

Heat Resistance: Maintains its properties even when tapping generates heat, potentially minimizing tool wear and thread deformation.

Lubricity: Low friction aids in achieving accurate tapered threads and minimizes force requirements.

Specialized Coatings

Chromium Nitride (CrN): Offers value in specific scenarios:

Diamond-Like Carbon (DLC): The extreme performance option:

Unmatched Hardness: Exceptional wear resistance for the most demanding materials or very high production volumes.

Super Low Friction: Optimizes material flow and thread forming, minimizing galling risks and ensuring high-quality threads.

Gas thread taps, with their specialized tapered design for creating leakproof connections, play a crucial role in industries where reliable gas and liquid transportation is vital. Companies like Baucor likely cater to the following sectors where their taps are essential:

Key Industries Relying on Gas Thread Taps

Why Choose Gas Thread Taps?

Tap Into Baucor's Expertise

Baucor's commitment to quality likely extends to their gas thread taps, designed to cater to these diverse applications. Contact us to find the perfect taps, matched to your specific pipe materials, thread standards, and project requirements.

Gas thread taps, with their specialized design for creating leakproof connections, are essential tools across numerous industries. This likely includes companies like Baucor, offering quality taps to meet diverse needs.

Why Choose Gas Thread Taps?

Durable Connections: Ideal for systems subject to pressure fluctuations or vibrations.

Gas thread taps, designed to create those crucial leakproof connections, find use in a spectrum of machines due to their ability to cut internal threads in pipes and fittings. Their suitability depends on the material, required precision, and production goals. Companies like Baucor likely offer taps designed to match the needs of these machines.

Manual and Semi-Automated Options

CNC Automation for Precision and Productivity

Beyond the Machine: Essential Considerations

A straight flute tap, also known as a hand tap, is a common cutting tool used to create internal threads in a pre-drilled hole. They're often used manually but also work in machines like drill presses.

Machine screw taps are specialized tools designed to cut internal threads in pre-drilled holes. These threads are standardized to accept machine screws, providing secure and reliable fastening solutions across a wide range of industries and applications.

Combination machine taps are specialized tools designed to streamline the thread-cutting process by combining multiple operations into a single tap. This makes them particularly useful in production environments where minimizing tool changes and optimizing cycle times are crucial.

Bent Shank Taps are a specialized type of tap designed with a bent or curved shank, distinguishing them from the straight shanks typically seen on most taps. This design is particularly useful for reaching inaccessible or awkward areas where a straight tap cannot be properly aligned or rotated.

Choosing the right gas thread tap is key to successful installations and leak-proof connections, but sometimes you need more than the tool itself. Baucor, as a potential provider of high-quality taps, might offer several resources and expertise to guide your selection and optimize your processes:

Potential Areas of Design and Engineering Support

BAUCOR offers custom manufacturing and engineering solutions tailored to your specific needs, across various industries.

BAUCOR's engineers can review your design and provide feedback to improve manufacturability, cost effectiveness, and efficiency.

Unlike standard cutting taps, gas thread taps are designed specifically to create tapered, leakproof threads. Their specialized design follows a combination of industry standards, manufacturer choices, and considerations specific to gas line applications. Let's dive into the key design elements:

Crucial Design Considerations

Standards and Specifications

Taper: This is the defining feature!

Flutes: While not for chip removal, flutes play a role:

Pilot Hole:

Chamfer

Material

Surface Treatments (Optional)