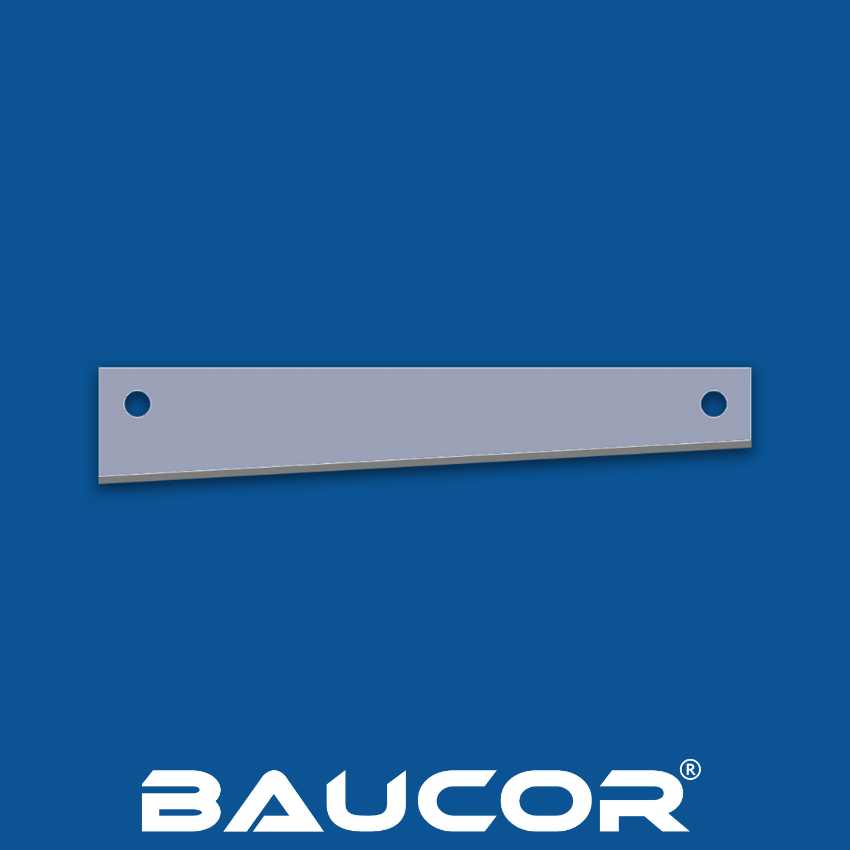

A straight blade is a knife with a sharp edge on one or both sides. They are typically made from high-carbon steel and are very hard and durable.

Straight blades are one of the most common blades used in cutting food and for self-defense. They can also be used for other tasks such as drilling, grinding, and shaping. The blade can be made from various materials, such as carbide and stainless steel. The sharpness of a straight blade makes it ideal for cutting through rigid materials like wood, metal, and plastic.

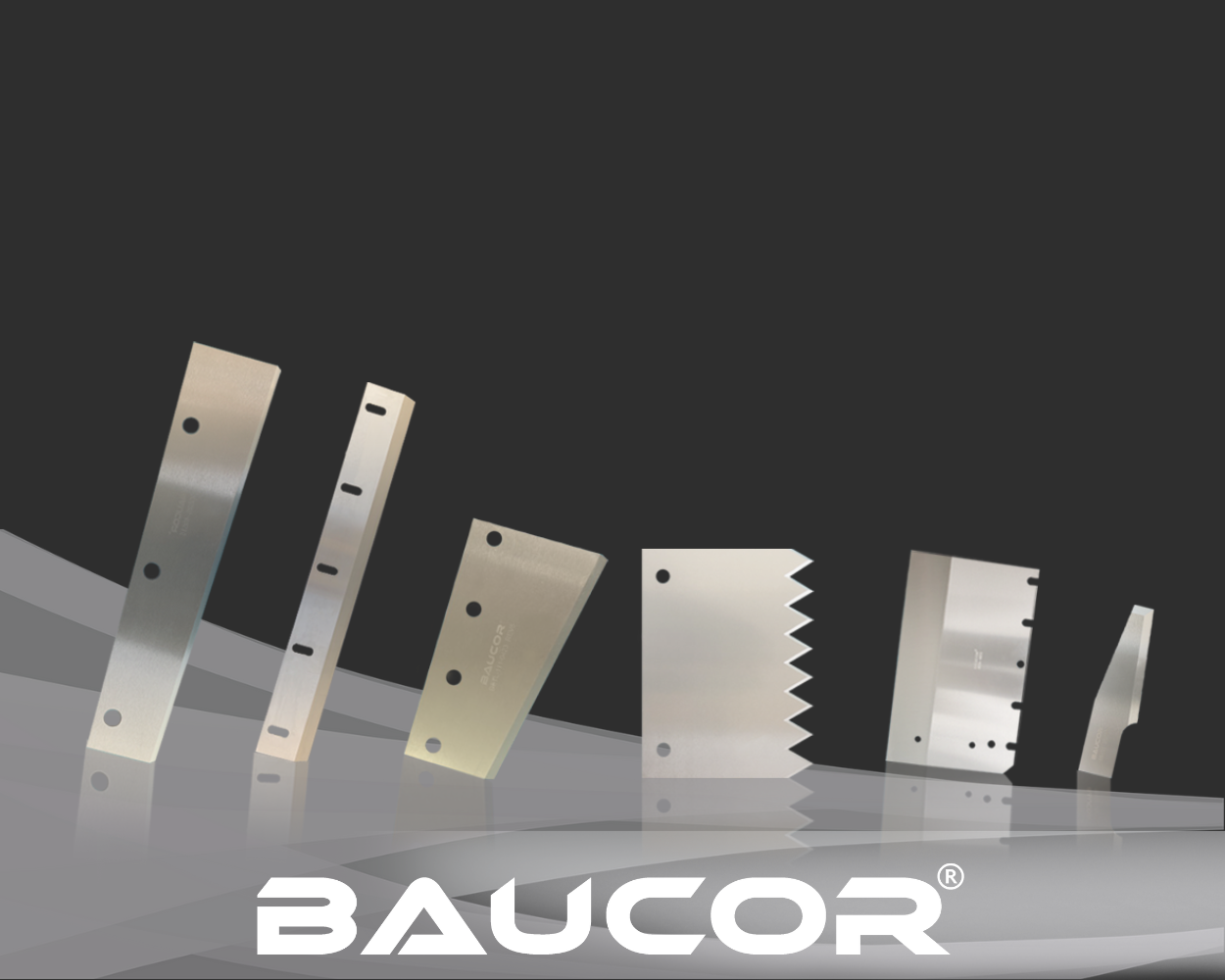

If precision, quality and short lead time all matter for your straight blades and flat blades, then you are at the right place. Baucor manufactures and supplies literally thousands of both standard and custom size precision straight blades and flat blades for all kinds of use from slitting, cutting and perforating to rewinding. Whether you need a smooth edge straight blade or a straight knife with toothed, serrated, scalloped, perforation and saw tooth forms, or even more complex tooth forms, Baucor can turn your design into straight blades and flat blades in just days. It doesn't matter if it's paper cutting, food slicing, packaging, rubber converting, film cutting or foil converting, regardless of what it's used for, our straight blades and flat blades are exceptionally made from quality ground hardened tool steels and stainless steel as well as Tungsten Carbide or made with Tungsten Carbide tipped.

English

English