Baucor's Holistic Approach: Conceptualization to Timely Delivery

In today's fast-paced manufacturing world, efficiency and productivity are critical for success. That's where Baucor's end-to-end solutions come into play. By offering a comprehensive range of services from concept to delivery, Baucor ensures that every step of the manufacturing process is streamlined and optimised.

From initial design and prototyping to final production and distribution, Baucor takes care of it. Their experts work closely with clients to understand their specific needs and requirements. This collaborative approach allows Baucor to develop customised solutions that meet and exceed customer expectations.

This outline explores Baucor's unique approach to delivering end-to-end solutions in the manufacturing sector.

Concept Development

A. Initial Consultation and Needs Assessment

Baucors is excellent at offering its clients end-to-end solutions during the concept creation phase. They guarantee a thorough grasp of the client's demands through an initial consultation and needs assessment. Because of this, they may customise their offerings to fit the unique requirements and objectives of every project.

Additionally, Baucors considers factors unique to the business while developing concepts. They know that every industry has its own set of problems and demands, and they use this knowledge to create solutions that successfully take these aspects into account.

Baucors has made a name for itself as a reliable partner in providing complete solutions from concept to delivery by focusing on the needs of its clients and paying close attention to specifics unique to their business. Their unwavering dedication to excellence is evident at every stage, guaranteeing their clients' success.

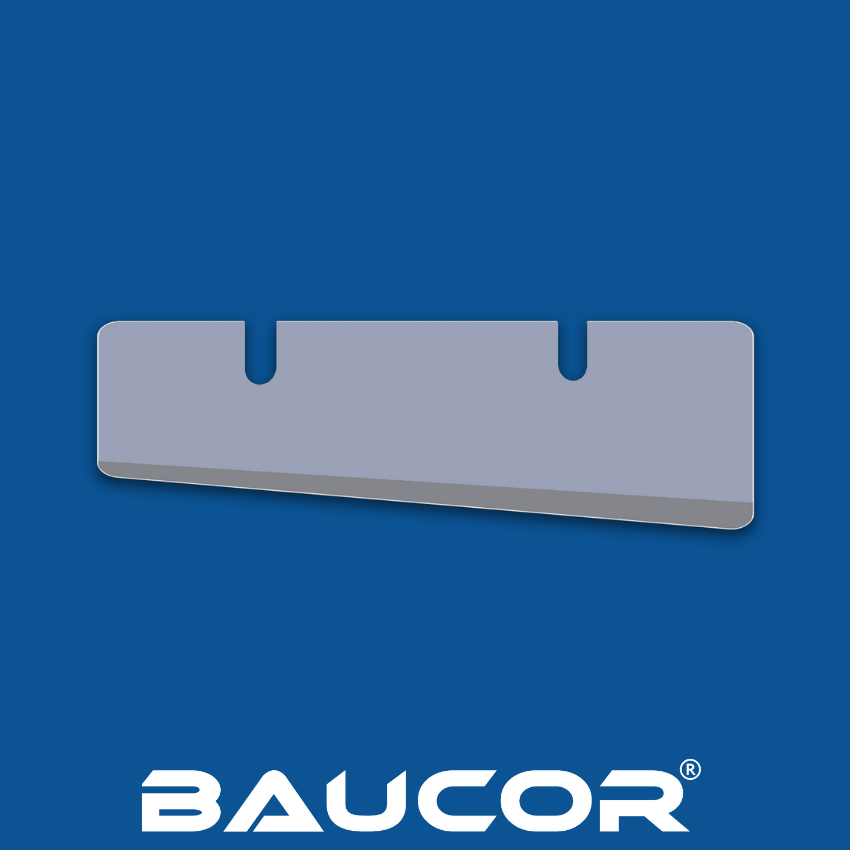

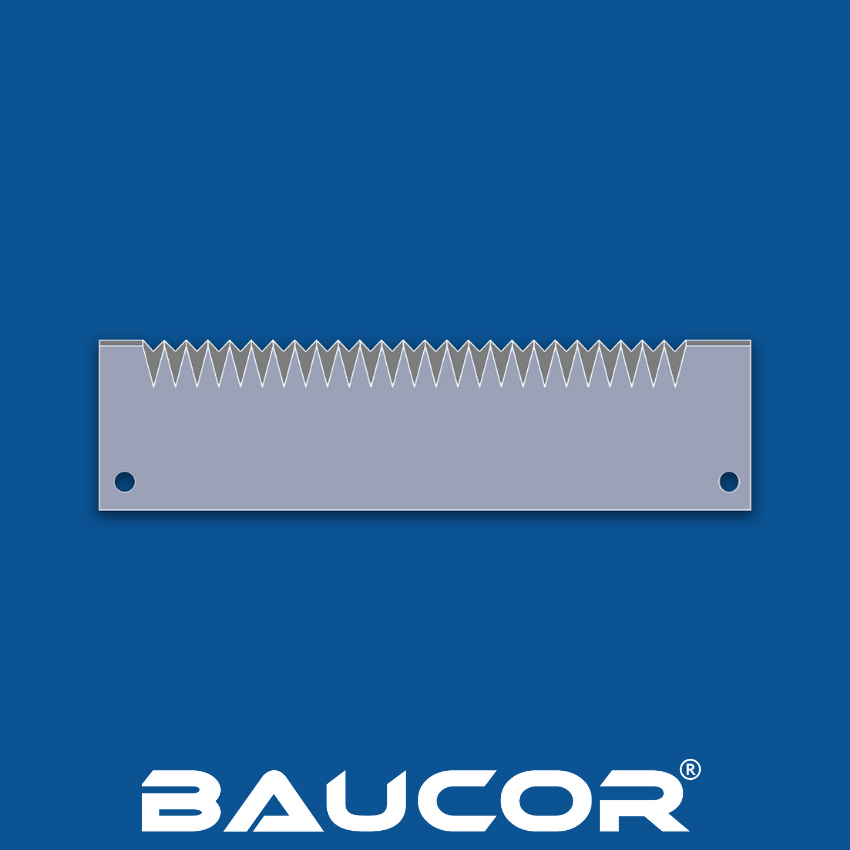

Baucors' concept development approach lays the groundwork for success, whether they are creating cutting-edge packaging solutions or unique cutting equipment. They can provide customised solutions that go above and beyond customer expectations because they have a deep awareness of client requirements and take industry-specific considerations into account.

B. Design and Engineering

Baucors focuses on practical design and engineering for concept development. Thanks to their team of talented specialists, they have the know-how to transform concepts into concrete things.

Baucors is aware that each project is distinct and needs a customised strategy. To ensure that the intended result is well understood, they start by carefully examining the client's needs. After this initial conversation, they can identify industry-specific design factors.

Baucors' in-house designers scrutinise every aspect. Their team uses cutting-edge tools and software to precisely and effectively bring concepts to life. They have the technology required for precise depiction, whether working with 2D drawings or 3D modelling.

Using cutting-edge technologies, Baucors can optimise the entire design and engineering process. They cover all ground regarding quality control, from CAD/CAM software for accurate measurements to simulation tools for functionality testing.

Using cutting-edge software and tools and their in-house design capabilities, Baucors maximises productivity while upholding the highest quality standards throughout the concept creation phase.

C. Prototyping

Prototyping is crucial in the development process when bringing a concept to life. Baucors knows the value of quick and effective prototyping techniques that transform ideas into finished goods.

Baucors produces prototypes fast by using state-of-the-art methods like 3D printing, CNC machining, and laser cutting. These tools allow us to quickly iterate ideas depending on client feedback and precisely replicate designs.

Prototypes test functionality and performance as well as build objects. Prototypes are put through rigorous testing by Baucors to make sure they adhere to the necessary standards and requirements.

The feedback loop is also a crucial component of our prototyping procedure. We regularly solicit client feedback at every level, enabling us to adjust designs to their requirements and preferences.

GET A QUOTE

Manufacturing Process

A. Material Selection

Baucors is known for its superior material standards. Strict adherence to high-quality material standards guarantees that every manufactured component meets or surpasses industry standards. Their dedication to excellence distinguishes them and ensures that their customers obtain items with remarkable robustness and dependability.

Additionally, Baucors is aware that every project may have particular material requirements. To meet this demand for personalisation, they provide bespoke material selections according to project requirements. Baucors can acquire and work with various materials, whether a specific metal alloy or a unique blend of polymers.

By offering both specialised solutions and high-quality material standards, Baucors effectively proves its capacity to suit the different needs of its clients. Their ability to choose and use suitable materials significantly produces high-quality goods for various sectors.

Baucors' commitment to producing outstanding end-to-end solutions goes beyond selecting the appropriate materials and encompasses all phases of conceptualisation to realisation. Every process step, from design and prototype to precise machining and final assembly, is carried out with the highest level of care.

B. Precision Manufacturing Techniques

Baucors is a precise production leader because of its advanced machinery and cutting-edge methods. Because they strive for perfection, they ensure every step of the production process is accurate.

At Baucors, they are aware that precise outcomes require the use of top-notch equipment. For this reason, they spend money on cutting-edge machinery that combines efficiency, accuracy, and speed. These devices have advanced features to boost output while upholding the highest quality standards.

Baucors uses cutting-edge technology at every production level, from computer-controlled lathes to high-speed CNC milling machines. They can satisfy demanding client needs and provide consistent output as a result.

Strict adherence to quality control procedures is necessary throughout the precision production process. Baucors prioritises this throughout.

They use a thorough quality control system with thorough inspections at different production stages. Experts in their field carefully examine every part, utilising state-of-the-art measurement tools to guarantee precise dimensions.

C. Assembly and Finishing

At Baucors, we recognise the value of accuracy and close attention to detail in each stage of the production process. Each item is painstakingly and expertly assembled by their trained specialists, guaranteeing that every piece fits perfectly.

Baucor staff has extensive experience working with various items, from sophisticated industrial machines to intricate medical gadgets. Strict procedures and industry standards ensure the highest quality during assembly.

Their strict quality control begins after assembly. Every product is put through a rigorous testing process to ensure it is durable and functional. With the help of their cutting-edge testing apparatus, they can find any possible problems or flaws before delivery.

During the completion step, they meticulously consider aesthetic aspects and functional tests. Their expert artisans provide the finishing touches to every product, ensuring that its look lives up to the expectations of their clients.

Using cutting-edge technologies and highly skilled personnel, Baucors guarantees that each product that leaves their facilities meets exacting quality standards.

D. Quality Assurance

i) Comprehensive Testing

Baucors values industry standards and exceeds them. They innovate and enhance while meeting benchmarks. Baucors keeps its products high-quality by staying current on technology and regulations.

Baucors tests extensively to ensure quality. Products undergo extensive testing before reaching customers. That includes thorough inspections at each manufacturing stage to discover faults and defects.

Baucors uses cutting-edge measurement and analytical equipment to ensure manufacturing uniformity. It lets them spot even minor deviations from specifications quickly.

Baucors' strict in-house testing procedures complement their industry standards and quality assurance. They inspect raw materials, components, prototypes, and final goods before release.

Baucors may closely monitor production and product integrity by executing these tests internally rather than depending on third-party inspectors or suppliers' certifications. This attention to detail ensures only high-quality products leave their factories.

ii) Certification and Compliance

Baucors takes great pride in its commitment to quality assurance, which includes meeting international standards and complying with regulatory requirements. These two factors are crucial to producing products that meet client expectations and industry standards.

Baucors must meet international requirements for worldwide customers. They recognise the necessity of providing items that work worldwide without difficulties. Baucors strictly follows worldwide rules and criteria set by relevant organisations.

Baucors' production method also requires regulatory compliance. They recognise that different countries have varied industry norms and requirements. They guarantee that their items conform to these laws to avoid legal or safety difficulties.

Baucors ensure their high-quality goods may be used across markets by prioritising international standards and regulatory compliance.

E. Delivery and Implementation

1. Customized Packaging and Shipping

In Baucors' manufacturing process, customised packing and shipment are vital. They know every product has different packaging needs and ensure it gets delivered safely. With years of experience in the field, they have created cutting-edge solutions that satisfy even the most demanding requirements.

i) Safe and efficient packaging solutions:

Baucors puts safety first by providing robust packaging options for all types of products. They have the know-how to create unique packaging that safeguards your items in transit, whether bulky industrial pieces or delicate electronic components. Through the use of premium materials and cutting-edge methods, they guarantee that your purchases arrive undamaged.

ii) Global logistics capabilities:

Although international product shipping can be complicated, Baucors makes the process easier with its global logistics capabilities. They can effectively handle international shipments since they have solid relationships with reliable freight forwarders and carriers around the globe. Baucors takes care of every detail, from managing customs clearances to organising deliveries, so you can concentrate on expanding your company.

Baucors' comprehensive manufacturing process, which includes personalised packaging and shipping, and their worldwide logistical expertise, means you can entrust them with every step of taking your product from conception to completion.

When collaborating with Baucors, you'll have a dependable partner who will relentlessly strive to realise your vision. Their quality ensures that every step of the manufacturing process goes well, from product creation to shipping to pleased customers worldwide.

2. On-site Implementation Support

i) Assistance with installation:

Baucors provides skilled installation when your item is ready for delivery. Their trained specialists will assist you in setting up your equipment correctly throughout the process. You may be sure that your new machinery will be up and running quickly thanks to their knowledge.

ii) Training and operational guidance:

Baucors is aware of the significance of appropriate training for achieving peak performance and extending the life of their goods. They customise their in-depth training sessions to meet your demands. Their staff will walk you through every step of equipment use and ensure you fully grasp its features.

Operational guidance continues beyond training; Baucors firmly believes in establishing enduring connections with its clients by providing continuous help as required. Their committed team is always available to assist, whether you have enquiries or require troubleshooting assistance later.

The dedication of Baucors to client pleasure goes beyond the provision of goods. They guarantee a smooth process from beginning to end with on-site implementation support that includes installation help and thorough training programmes.

GET A QUOTE

F. After-Sales Support

1. Customer Service

Baucors understands the importance of after-sales assistance. They stand out for their client service. Their committed support team ensures clients receive timely assistance when needed.

Baucors knows every consumer has distinct needs. So, they offer support and advice throughout the process. Their educated staff is always available to answer enquiries about product specs or equipment use.

Baucors stands out by going above and beyond for customers. In addition to selling items, they create long-term client connections. They carefully assess your needs and customise solutions.

Baucors' assistance continues following the transaction. They develop lasting relationships with clients by providing post-delivery support. Their dedication guarantees you all-important support throughout your production journey.

Baucors' after-sales support goes beyond selling equipment to providing excellent service throughout. A dedicated support team and ongoing assistance ensure you have everything you need for manufacturing success.

2. Maintenance and Upgrades

Baucors know how crucial routine maintenance is to keeping equipment operating efficiently. They provide regular cleaning, lubrication, calibration, and inspections as part of their scheduled maintenance services. Maintaining a proactive maintenance routine will help you stop possible problems before they become serious ones. It increases overall production, decreases downtime, and prolongs the life of your equipment.

Process optimisation and continual improvement are essential to staying competitive in today's fast-paced manufacturing world. Recognising this requirement, Baucors provides upgrades to improve the functionality of its products.

These upgrades, which might be new technology integrations or design changes, are intended to increase speed, accuracy, efficiency, or any other individually customised factor to match your changing needs.

Conclusion

In conclusion, Baucor's end-to-end solutions exhibit conceptualisation, production, and delivery strengths. The company's commitment to cutting-edge technology, quality control, and client satisfaction has yielded successful project outcomes. Looking forward, Baucor's dedication to innovation positions it for continued excellence in manufacturing solutions, ensuring a dynamic and reliable partnership for clients in the evolving industrial landscape.

English

English