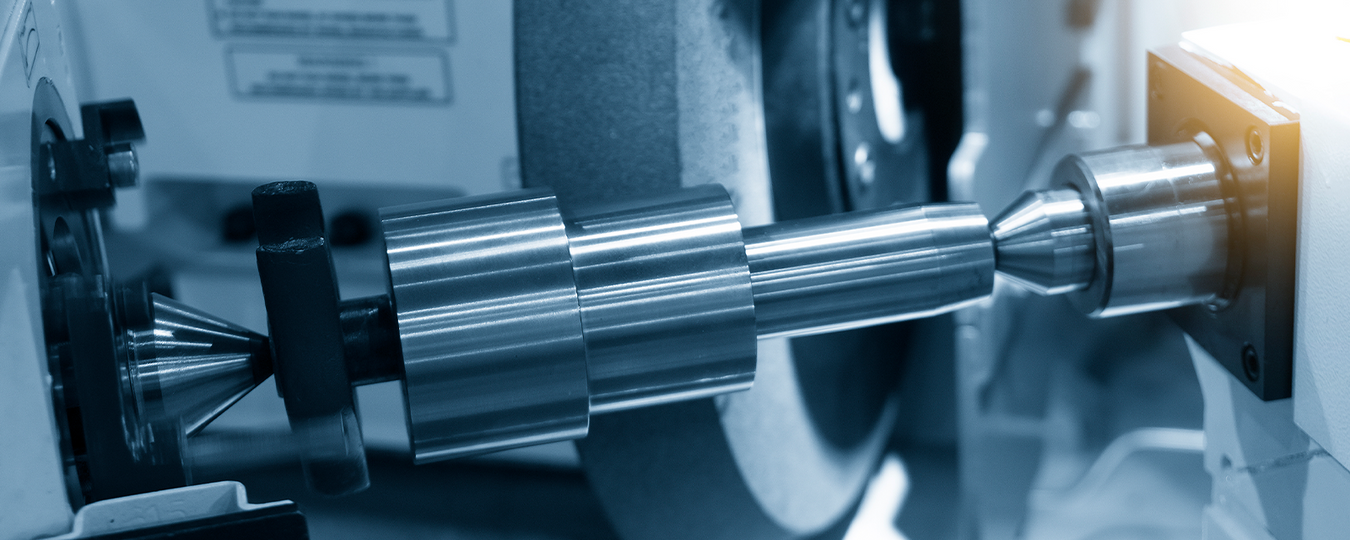

PRECISION GRINDING TECHNOLOGY

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

Vegetable-fruit knives are specifically designed for cutting through both vegetables and fruit. They are typically larger and sharper than your average kitchen knife, making them ideal for quickly and efficiently slicing through large quantities of produce.

Vegetable-fruit knives are usually made from a stainless-steel blade and are designed to be sharp and durable to ensure precise cuts and long service life. The blade is often serrated to make sure it can easily slice through tough-skinned fruits and vegetables.

Food processing blades or as some call food processing knives are used for cutting operations such as chopping, slicing, dicing, peeling. Selecting the correct stainless steel type for food cutting operation is extremely important in food processing due to the acidic nature of food leading to faster wear of the steel, and potentially leading to contamination of the food with the oxidation build-up on the blade surface.

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

BAUCOR® is highly specialized in manufacturing custom industrial blades. If you need your knives manufactured to your exact requirements, please contact us now.

Baucor manufactures precision quality custom and standard size food processing knives and food cutting blades from high grade ground hardened stainless steels for food processing industries including fresh, dry fruit & vegetable processing, meat and poultry processing, seafood processing, bakery including croissant, cake and bakery for applications like cutting, slicing, dicing and many others. Our food processing knives and blades are for all food processing applications imaginable including but not limited to slicing, cross cutting, die cutting, guillotine cutting, press cutting. Our food processing knives and blades come in straight, circular, pointed tip, toothed, serrated, scalloped, perforated shapes and as interlocked blades for guillotine cutting. One of our specialties is to manufacture any type and shape of custom food processing knife without limits. If you have a drawing, sketch or written specifications for the blade you need, please contact us now for a quick quote. We can even design a specific blade for your application.

Baucor, as a trademark of Norck, proudly operates under ISO 9001:2015 certification.

Key aspects include:

This certification reflects Baucor’s ongoing commitment to quality and performance.

Click here to view our ISO certification.

Small or large, BAUCOR® manufactures all types and shapes of precision circular blades in nearly all materials available in the market.

Whether it is 5mm or 2500mm long, BAUCOR® has the right capacity and advanced capabilities to manufacture precision industrial blades.

Did you know that BAUCOR® has manufactured tens of thousands of precision punch blades? Get your quote today!

Manufacturing custom industrial blades is no easy task that anyone can handle. That's why BAUCOR® is here to help!

There are many advantages of using vegetable-fruit knives:

BAUCOR® manufactures razor and straight blades as small as 5mm and as large as 2500mm.

Punch blades must be made to exact specs. Turn to BAUCOR® just like thousands of customers around the world.

Whether you need circular slitter blades or flat slitter blades, BAUCOR® is here to turn your design into precision part.

BAUCOR® manufactures precision top quality toothed blades in all shapes and form.

Need to make a slit or cut through your material as precise as possible? BAUCOR® pointed blades are of highest quality in the market.

Top and bottom shear and slitter blades from BAUCOR®.

American or European style! BAUCOR® has the correct holder for you!