PRECISION GRINDING TECHNOLOGY

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

A splice knife is a cutting tool to cut and join two pieces of material. It is typically a large, heavy-duty knife with a sharp, serrated edge that can easily slice through thick materials. Some industrial splicing knives may have a pointed tip for precise cuts or a curved edge for cutting curves or circles.

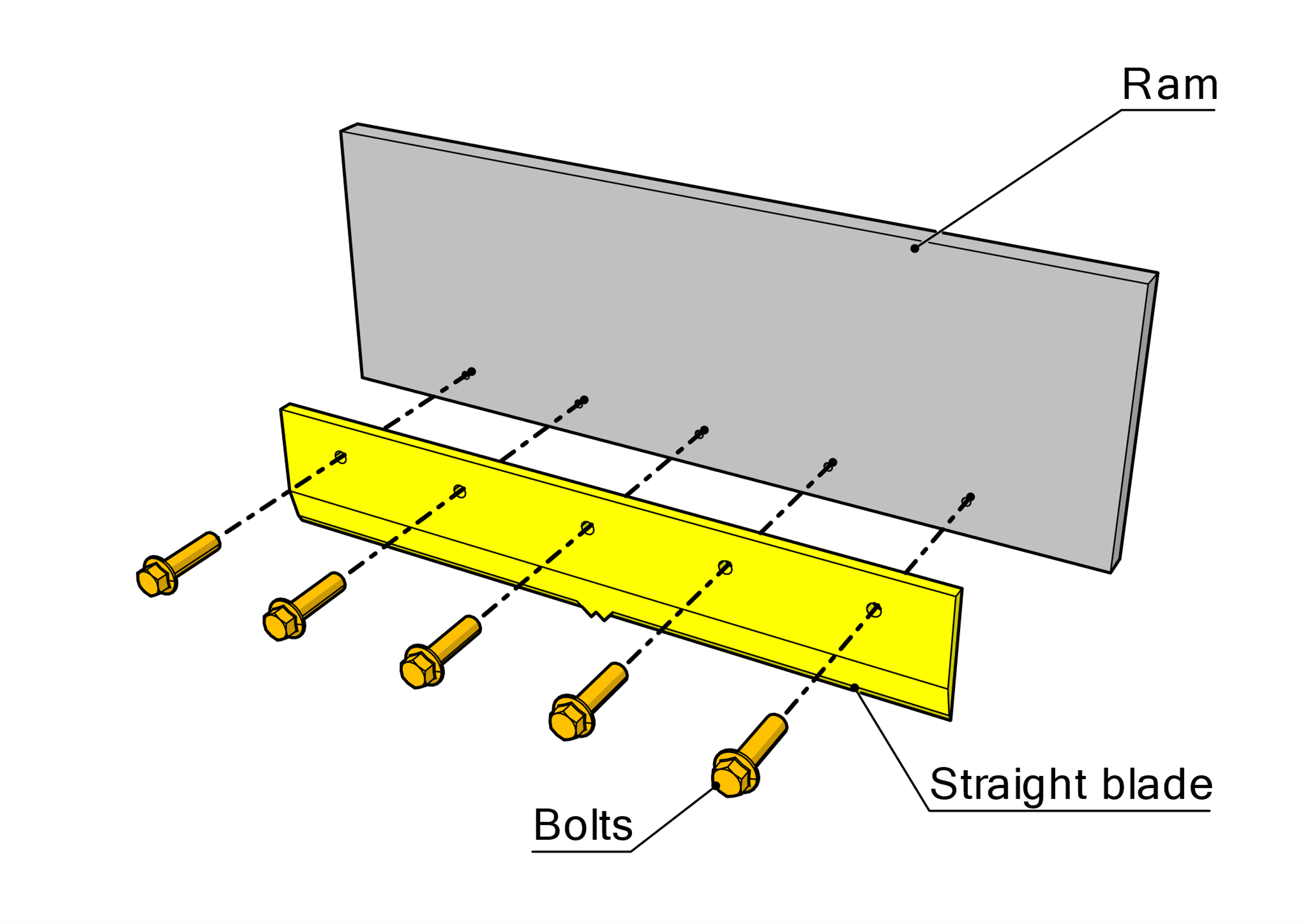

We offer curved and straight splicing blades. Splicing blades are typically made from stainless steel or carbide tungsten to ensure long-lasting performance and reliability. They are used in various industries, including textiles, printing, and plastics.

Baucor has the experience to manufacture all shapes and kinds of industral splicing blades and splice knives. We manufacture and supply literally thousands of both standard and custom size precision splice knives (splicing blades) for all kinds of industries. Whether you need custom or standard off-the shelf splice knives (splicing blades), Baucor can turn your desing into a blade in just days. It doesn't matter if it's paper cutting, packaging or plastic converting, regardless of what it's used for, our splice knives (splicing blades) are exceptionally made from quality ground hardened tool steels and stainless steels.

Baucor, as a trademark of Norck, proudly operates under ISO 9001:2015 certification.

Key aspects include:

This certification reflects Baucor’s ongoing commitment to quality and performance.

Click here to view our ISO certification.

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

BAUCOR® is highly specialized in manufacturing custom industrial blades. If you need your knives manufactured to your exact requirements, please contact us now.

We are highly specialized in manufacturing custom splice knives (splicing blades) per sample and drawing. If you need your splice knives (splicing blades) manufactured to your exact requirements, please contact us now to see how we can make high quality industrial blades and machine knives exceeding your requirements at a competitive price and always delivered right on time.

Small or large, BAUCOR® manufactures all types and shapes of precision circular blades in nearly all materials available in the market.

Whether it is 5mm or 2500mm long, BAUCOR® has the right capacity and advanced capabilities to manufacture precision industrial blades.

Did you know that BAUCOR® has manufactured tens of thousands of precision punch blades? Get your quote today!

Manufacturing custom industrial blades is no easy task that anyone can handle. That's why BAUCOR® is here to help!

There are many advantages of using splice knives:

BAUCOR® manufactures razor and straight blades as small as 5mm and as large as 2500mm.

Punch blades must be made to exact specs. Turn to BAUCOR® just like thousands of customers around the world.

Whether you need circular slitter blades or flat slitter blades, BAUCOR® is here to turn your design into precision part.

BAUCOR® manufactures precision top quality toothed blades in all shapes and form.

Need to make a slit or cut through your material as precise as possible? BAUCOR® pointed blades are of highest quality in the market.

Top and bottom shear and slitter blades from BAUCOR®.

American or European style! BAUCOR® has the correct holder for you!