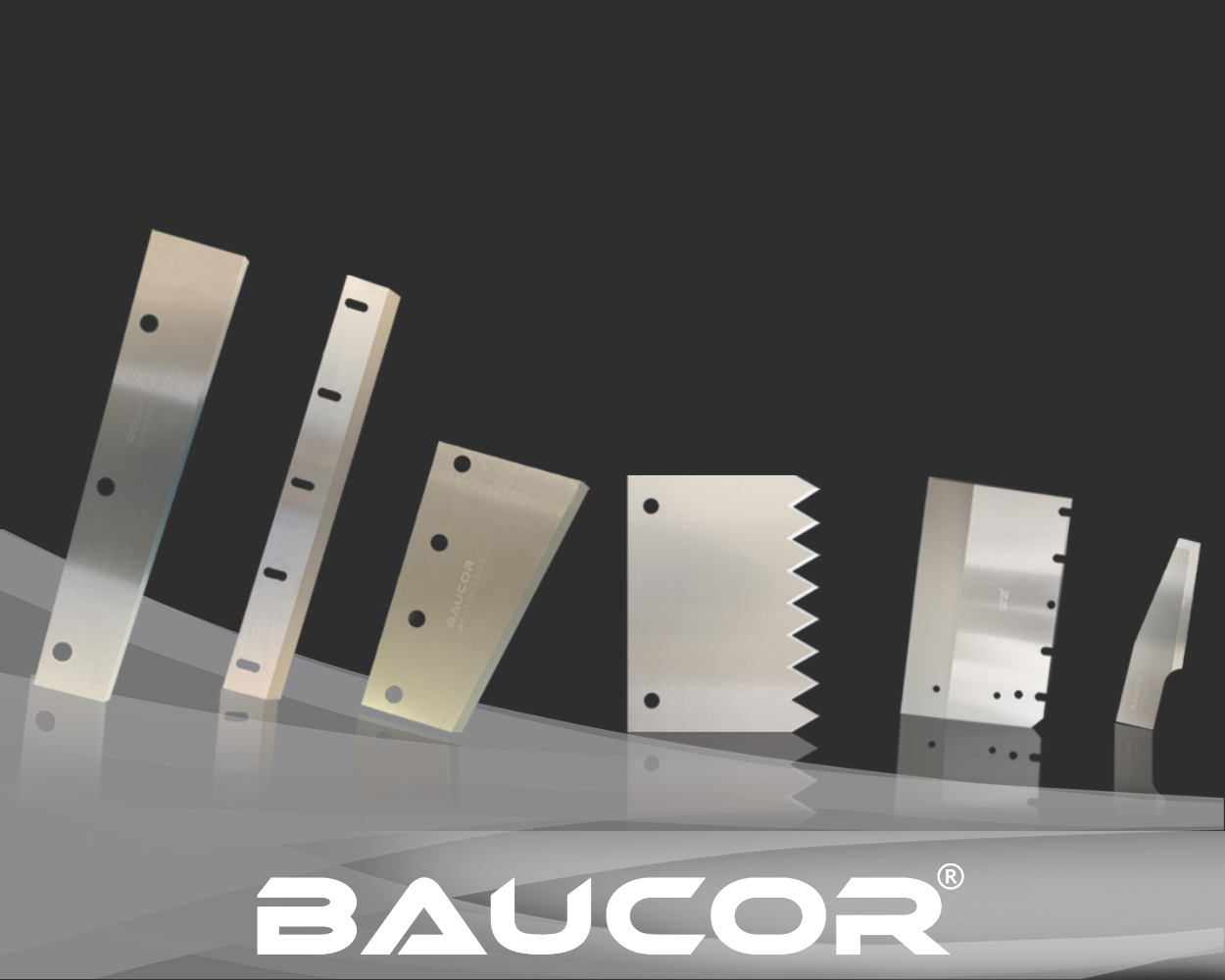

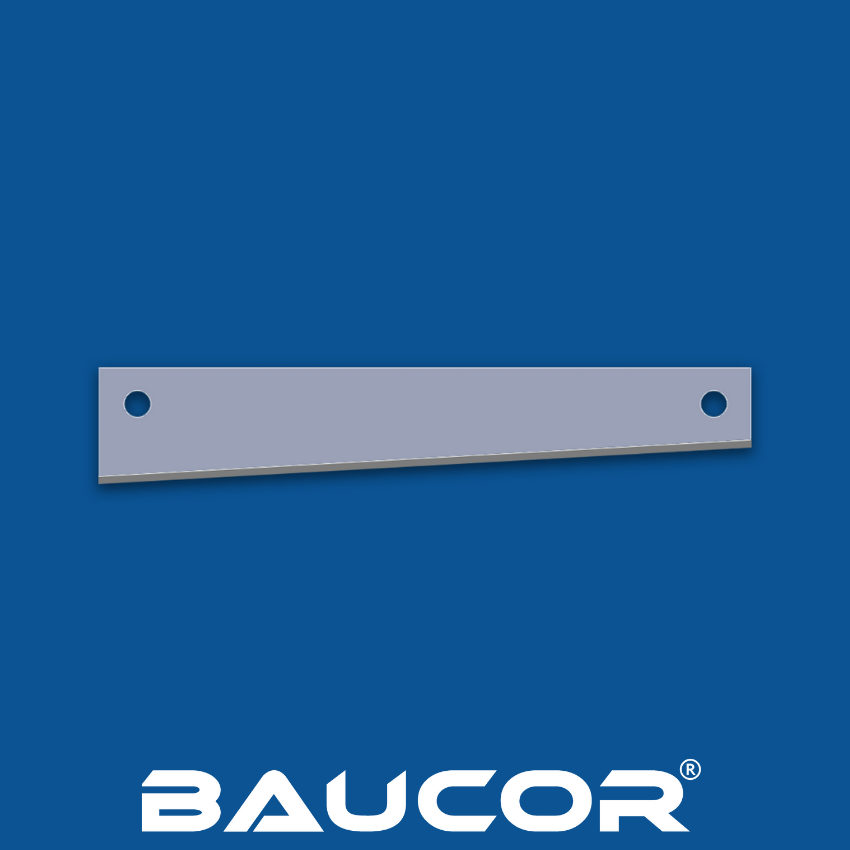

Flat-straight slitter blades are a type of cutting tool used in the process of slitting, which involves cutting a roll or sheet of material into smaller strips or widths. Slitter blades are typically made of high-carbon steel and are designed to withstand the demands of the slitting process.

They are typically used in slitting machines, which are used to cut materials such as paper, film, foil, nonwovens, and other types of sheet materials. The flat-straight slitter blades are used in many industries, including the paper and packaging, printing, and converting industries.

From a size of less than 1" up to 100" long, Baucor manufactures premium quality straight slitting knives and flat slitter blades. Contact us to find out more. Baucor manufactures and supplies both standard and custom size precision straight slitting knives and flat slitter blades for most slitting applications. Baucor can turn your design into straight slitting knives and flat slitter blades in just days. It doesn't matter if it's paper slitting, food slitting, packaging, rubber cutting, meat, film cutting or foil converting, regardless of its use, our flat slitting blades and knives are exceptionally made from quality ground hardened tool steels and stainless steel as well as carbide.

English

English