Trends and Innovations in Circular Slitter Knives at Baucor

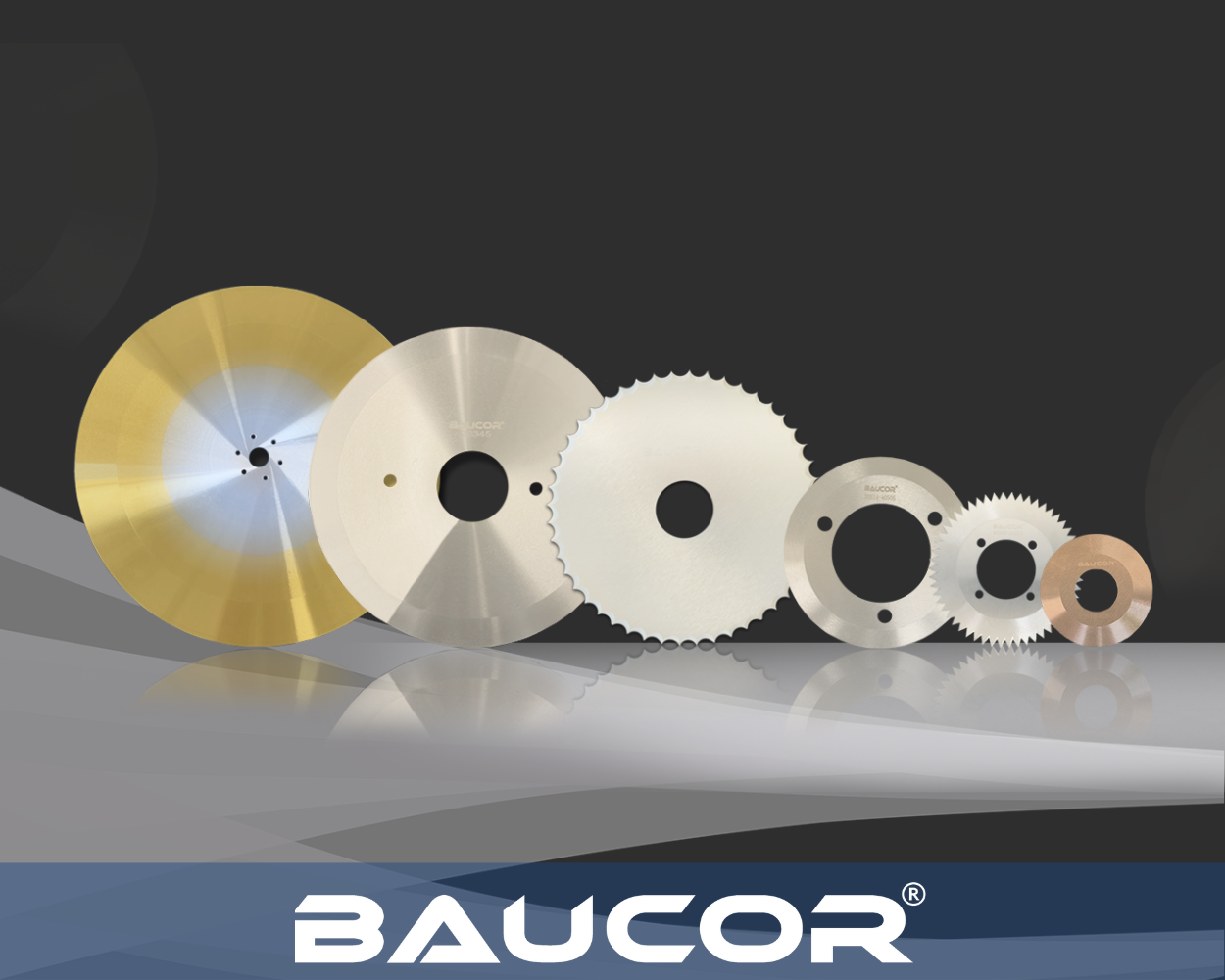

Circular slitter knives are an essential tool in various industries, including paper, film, plastics, and metal processing. These blades are critical to manufacturing because they cut materials precisely and efficiently. Baucor is a renowned manufacturer of circular slitter knives with a strong reputation for quality and innovation. With decades of experience in the industry, Baucor has established itself as a leader in producing high-performance blades that meet the diverse needs of its customers.

Innovation is at the heart of Baucor's approach to manufacturing industrial blades. The company continuously invests in research and development to stay ahead of market trends and technological advancements. This commitment allows them to deliver cutting-edge solutions that enhance productivity, durability, and performance. By embracing innovative technologies such as advanced materials and coatings, Baucor ensures its circular slitter knives have exceptional results across different applications. These innovations not only extend blade life but also minimize downtime for maintenance or replacement.

As technology continues to evolve at an unprecedented pace across industries today - innovation becomes indispensable. Manufacturing blades like circular slitter knives must stay ahead. Manufacturers must constantly strive towards developing innovative solutions that enhance performance while reducing costs and downtime.

Here, we'll discuss some exciting trends in circular slitter knives' design and manufacturing.

Historical Context

Evolution of Slitter Knives Over Time

Long before the age of machines, humans sought ways to cut and shape materials efficiently. Simple portable blades fashioned from stone or animal bones were the oldest tools. They were cutting instrument technology developed along with civilizations.

Due to its durability and sharpness, metal supplanted stone as the most common blade material in ancient times. Craftspeople were able to cut through a variety of materials thanks to these early slitter knives.

Manufacturing techniques saw tremendous breakthroughs throughout the 18th-century Industrial Revolution. Steel production led to the development of more substantial and more adaptable slitter knives than ever before. They advanced faster with powered technologies.

The 20th century saw a sharp increase in the demand for effective cutting solutions as industries grew. The outcome was customized circular slitter knives that were rapid but precise.

Advances in metallurgy have led to even more opportunities for these indispensable instruments over time. High-carbon steels improved the toughness and edge retention of the blade, guaranteeing sustained cutting performance in harsh environments.

Now, fast-forward to the present day. By introducing cutting-edge materials like tungsten carbide into its designs, Baucor has raised the bar for innovation in circular slitter knives. Tungsten carbide is well-known for its exceptional strength and wear resistance, guaranteeing excellent performance and endurance even in demanding applications.

To meet the diversified needs of the industry, Baucor provides a wide range of adaptations, including alternative tooth shapes and coatings made especially for paper, textiles, plastics, and metals!

From ancient stone blades to modern circular slitter knives, Baucor's history demonstrates how human ingenuity has continuously aspired to excellence in precision cutting solutions. So get comfortable—we're only getting started! As we delve deeper into the fascinating developments and trends influencing this vibrant sector, stay tuned!

Previous Standards and Materials Used

As we can see from the previous sections, circular slitter knives have come a long way in innovation and design. The historical background sheds light on how these fundamental instruments have developed over time, emphasizing the necessity of ongoing innovation and flexibility in response to shifting needs.

Producers such as Baucor have transformed the market by bringing new materials and specifications for circular slitter knives in recent years. Because of this, companies have increased precision, productivity, and cutting processes.

The days of relying just on conventional knife materials are long gone. Modern alloys with superior hardness, durability, and wear resistance, such as tungsten carbide and ceramic coatings, have supplanted them. Circular slitter knives are guaranteed to stay sharp for extended periods without sacrificing performance, thanks to these contemporary materials.

Modern manufacturing methods like laser cutting and EDM wire-cutting allow advanced blade designs that perform well in challenging cutting applications. These innovations decrease downtime by regular sharpening or replacement requirements and increase efficiency.

Moreover, through innovative manufacturing techniques such as laser cutting or precise grinding processes using CNC machines, circular slitter knives can now be customized based on specific requirements. This level of customization enables appropriate blade geometry for varied materials and accurate tolerances.

Furthermore, because of Baucor's commitment to customization, companies can have circular slitter knives made just for their needs. Every element, including size variations, tooth configurations, and edge profiles, can be tailored to meet the needs of each cutting application successfully.

Together, these developments and trends help sectors that need to make accurate cuts through various materials—like paper, plastic films, textiles, metals, or composites—maximize performance levels and open the door to increased efficiency and economy.

GET A QUOTE

Current Trends in Circular Slitter Knives

Let’s discuss some of the current trends in circular slitter knives these days!

Materials

High-speed steel (HSS) is a popular choice due to its exceptional strength and durability. It is perfect for applications involving the cutting of hard materials like metals or polymers since it can tolerate high temperatures without losing its cutting edge. Circular slitter knives made of HSS are renowned for their extended lifespan and resilience to sharpening even in harsh environments.

Tungsten Carbide is another material gaining popularity in this field. Because of Tungsten Carbide's exceptional wear resistance and extraordinary hardness, blades can withstand more wear and tear before needing to be replaced or sharpened. Manufacturers benefit from lower downtime and higher production as a result.

Advanced Ceramics offers a whole new level of precision and performance. Because of extreme hardness and low weight, these materials are ideal for situations where accuracy and speed are crucial. In fields where precise cuts with close tolerances are needed, such as the fabrication of electronics or medical equipment, advanced ceramic circular slitter knives perform exceptionally well.

As technology advances, we can expect further developments in the materials used for circular slitter knives. Innovative alloys and composites are the subject of ongoing research because they can improve performance further, from superior corrosion protection to increased heat resistance.

Coatings and Treatments

Coatings and treatments play a crucial role in enhancing the performance and durability of circular slitter knives. The functionality of these knives has been transformed by Titanium Nitride (TiN), Diamond-Like Carbon (DLC), and other surface improvements, creating new opportunities for various sectors.

Titanium Nitride (TiN) coating provides excellent wear resistance, reducing friction during cutting operations. It also improves the blades' resistance to corrosion, making them appropriate for use in challenging conditions. TiN-coated circular slitter knives last longer, which means less downtime for changing out the blades and more output.

Coatings made of diamond-like carbon (DLC) are renowned for having a low coefficient of friction and remarkable hardness. These coatings are perfect for high-demand cutting applications because they provide outstanding wear resistance even under harsh conditions. Circular slitter knives coated with DLC are excellent for cutting precisely and vibrating less.

Other surface treatments are available to enhance the performance of circular slitter blades further, in addition to TiN and DLC coatings. These include specific techniques that can improve the hardness and toughness of knife materials, including heat treatment or cryogenic treatment.

We should anticipate more advancements in coatings and treatments for circular slitter knives as technology develops. Manufacturers such as Baucor continuously investigate innovative approaches to improve blade performance by developing sophisticated surface improvement methods suited to particular industry requirements.

The functionality, durability, and effectiveness of circular slitter knives have improved by trends in material selection, including High-Speed Steel (HSS), Tungsten Carbide, and Advanced Ceramics; novel coatings, such as Titanium Nitride (TiN) and Diamond-Like Carbon (DLC); and additional surface treatments.

Edge Design

Regarding circular slitter knives, edge design is crucial in achieving optimal performance. Manufacturers can improve the sharpness and longevity of these blades by tailoring their angles to suit particular materials.

Every material has distinct qualities and needs for cutting. For this reason, adjusting the edge design is crucial to guaranteeing accurate cuts and extending the blade's life. An ideal angle makes it possible to slice materials like paper, plastic, or metal quickly and effectively without sacrificing quality.

One further significant advantage of edge design optimization is enhanced sharpness. Manufacturers may generate razor-sharp edges that effortlessly cut through materials by precisely calculating the angle. It increases output while guaranteeing precise and clean cuts every time.

It is equally crucial for circular slitter knives to be durable. They need to be strong enough to sustain intensive use for extended periods due to the continuous wear and tear they receive. These blades' improved angles increase durability, enabling them to hold their strength in demanding situations.

Businesses like Baucor are using innovative production processes like 3D printing to attain such precision in edge design optimization. That enables unmatched customization made especially for each application.

Customization and Precision Engineering

Customization and precision engineering are two key trends driving the evolution of circular slitter knives. Manufacturers are placing more and more emphasis on offering customized solutions to satisfy particular application needs. It implies that circular slitter knives are made and adapted to meet the specific requirements of various industries, guaranteeing top performance.

One way this customization is through advanced manufacturing techniques such as 3D printing. With the help of this cutting-edge technology, complex designs, and exact requirements can be realized with the highest level of accuracy. Manufacturers may achieve tighter tolerances and more complicated geometries with 3D printing, which improves cutting performance.

Moreover, precision engineering plays a crucial role in optimizing the functionality of circular slitter knives. Every detail, including the choice of blade material and edge shape, is meticulously crafted to guarantee optimal performance and durability. Superior materials and cutting-edge heat treatment techniques increase durability and wear resistance even more.

Incorporating innovative technology into circular slitter knives is another vital trend, alongside personalization and precision engineering. These blades have sensitive real-time data on cutting parameters like temperature, pressure, and speed. Manufacturers can use this data to optimize operations, keep a close eye on performance, and identify possible problems before they happen.

Sustainability and Circular Economy

Circular slitter knives keep up with the fast-changing world in which environmental consciousness and sustainability are becoming important considerations in every industry. Manufacturing trends and developments for these essential tools demonstrate a dedication to sustainable practices and the circular economy.

The growing use of recyclable and environmentally friendly materials in the manufacturing of circular slitter knives is one of the main factors causing change. To minimize waste and its environmental effect, manufacturers choose materials that can be readily recycled or repurposed at the end of their lives. These environmentally friendly materials guarantee that these knives get recycled into new items rather than ending up in landfills, in addition to helping to make the production process more environmentally friendly.

In addition, circular slitter knives made with precise engineering techniques now have a longer lifespan and require fewer repairs. That not only saves money but, over time, uses less material, making it a more sustainable strategy. Superior materials and cutting-edge production techniques, like 3D printing, enable producers to reach previously unheard-of performance and durability levels.

Regarding circular slitter knives, durability, and sustainability go hand in hand. These instruments' longer lifespans boost productivity for businesses while reducing downtime from replacement requirements. Because of this decrease in overall knife turnover, there is less waste produced during the production process.

Furthermore, customization is essential to guarantee the best performance for specific applications. Manufacturers can maximize efficiency while reducing energy consumption and material waste by customizing solutions created especially for various sectors or cutting requirements.

Eco-friendly methods like recycling, making durable products, and planning upkeep define circular slitter knife trends. Because of the industry's dedication to environmental responsibility, they can satisfy customers' cutting requirements while creating a greener future for everybody.

Future Outlook

Emerging Technologies and Materials

New materials and technology are making the future of circular slitter knives look more promising than ever. More customization and accuracy in slitting applications are essential as industries develop and call for more specialized solutions.

Additive manufacturing, or 3D printing, is a revolutionary technology with enormous promise. This innovative process allows for the creation of complex geometries and shapes that were previously unattainable using standard production procedures. Specialized circular slitter knives can be 3D printed to improve production and cutting efficiency.

Compared to traditional steel blades, carbide, ceramic, and diamond coatings offer improved wear resistance and durability. These superior materials not only increase the longevity of circular slitter knives but also improve the precision of their cuts.

Moreover, automation developments are opening the door to even higher accuracy in slitting applications. By utilizing automated systems that can precisely alter the blade's position, producers can guarantee a uniform cut quality for various materials and thicknesses. Industries that need to maintain precise tolerances in their production processes have opportunities because of this level of precision.

Customization and accuracy will undoubtedly continue to be at the forefront of innovation in circular slitter knives as we look to the future. The capacity to customize solutions by particular application requirements will keep boosting productivity and cutting down on waste and downtime.

Manufacturers can get more out of circular slitter knives by adopting cutting-edge materials with improved qualities and embracing advanced technologies like additive manufacturing. As these improvements spread throughout various industries, such as the packaging, textile, and automotive sectors, we can anticipate even more breakthroughs shortly!

GET A QUOTE

The Role of Sustainability in Future Developments

Sustainability will indeed play a role in the future of circular slitter knives. As consumers become more conscious of the effects on the environment and demand environmentally friendly products, manufacturers are incorporating sustainable practices into their product creation processes.

Future advancements must take sustainability into account in some crucial ways. The usage of ecologically friendly materials is one such element. Alternatives to conventional blade materials, which might be hazardous to the environment or challenging to recycle, are being investigated by manufacturers. They contribute to a more sustainable production cycle and reduce waste using recyclable and renewable materials.

Energy efficiency is yet another essential component. As technology develops, so does the potential to design industrial procedures that are more energy-efficient. It entails streamlining cutting methods, minimizing power consumption while running, and implementing intelligent automation systems that use resources as sparingly as possible.

Furthermore, encouraging sustainability is greatly aided by creating circular slitter knives that are long-lasting and reusable. Manufacturers can maximize waste generation over time while extending the life of these blades by emphasizing durability and fine craftsmanship.

Initiatives for recycling are also becoming more popular in the sector. Businesses are spending money on initiatives to help used circular slitter knives be adequately disposed of and recycled when their useful lives are ending so they don't wind up in landfills.

Conclusion

As we reach the end of this blog post, it is evident that circular slitter knives are continuously evolving to meet the demands of today's industries. From advancements in materials like carbide and ceramic to innovative design features such as serrated edges and multi-cut capabilities, these small but mighty blades have come a long way.

Businesses can gain from enhanced productivity, decreased downtime, and increased precision by adopting these technologies and trends. The ability to cut through various materials with ease allows for greater versatility in manufacturing processes. Modern innovations such as quick-change systems and longer-lasting blades enable businesses to maximize productivity in their operations.

But it's crucial to remember that following the newest trends is only one aspect of the jigsaw. Selecting a dependable vendor such as Baucor guarantees that you will have access to superior circular slitter knives that can endure the most rigorous uses. Our dedication to quality distinguishes us as industry leaders.

English

English