Baucor: Confronting Industrial Blade Market Challenges Head-On

In this fast-paced era of manufacturing and production, having the right blade can make all the difference. One name stands out when meeting the challenges of the industrial blade market: Baucor.

With years of experience and a relentless commitment to quality, Baucor has established itself as a leading player in the industry. From cutting-edge technology to skilled craftsmanship, they have mastered the art of crafting blades that meet and exceed expectations. But before diving into their journey, let's take a moment to understand why industrial blades are crucial in various industries.

Whether slicing through materials like paper or plastic or tackling challenging tasks like metal cutting or food processing, industrial blades play a vital role across multiple sectors. They are indispensable in packaging, textiles, automotive manufacturing, and medical devices. These resilient tools enable precise cuts with minimal waste and maximum productivity.

However, amidst increasing demand and evolving technologies, businesses operating in the industrial blade market face several challenges. As with any industry, the industrial blade market faces its fair share of challenges. This article will explore some hurdles and how Baucor rises above them with innovative solutions.

Baucor's Background and Evolution

A leading company in the industrial blade market, Baucor, has a fascinating past and development trajectory. Having established itself some decades ago, Baucor has developed gradually to become a well-known brand in the industry.

Since its founding, Baucor has advanced thanks to some significant accomplishments. Baucor has grown throughout, from adding new goods to entering new markets. Innovation and consumer satisfaction have driven the company's success.

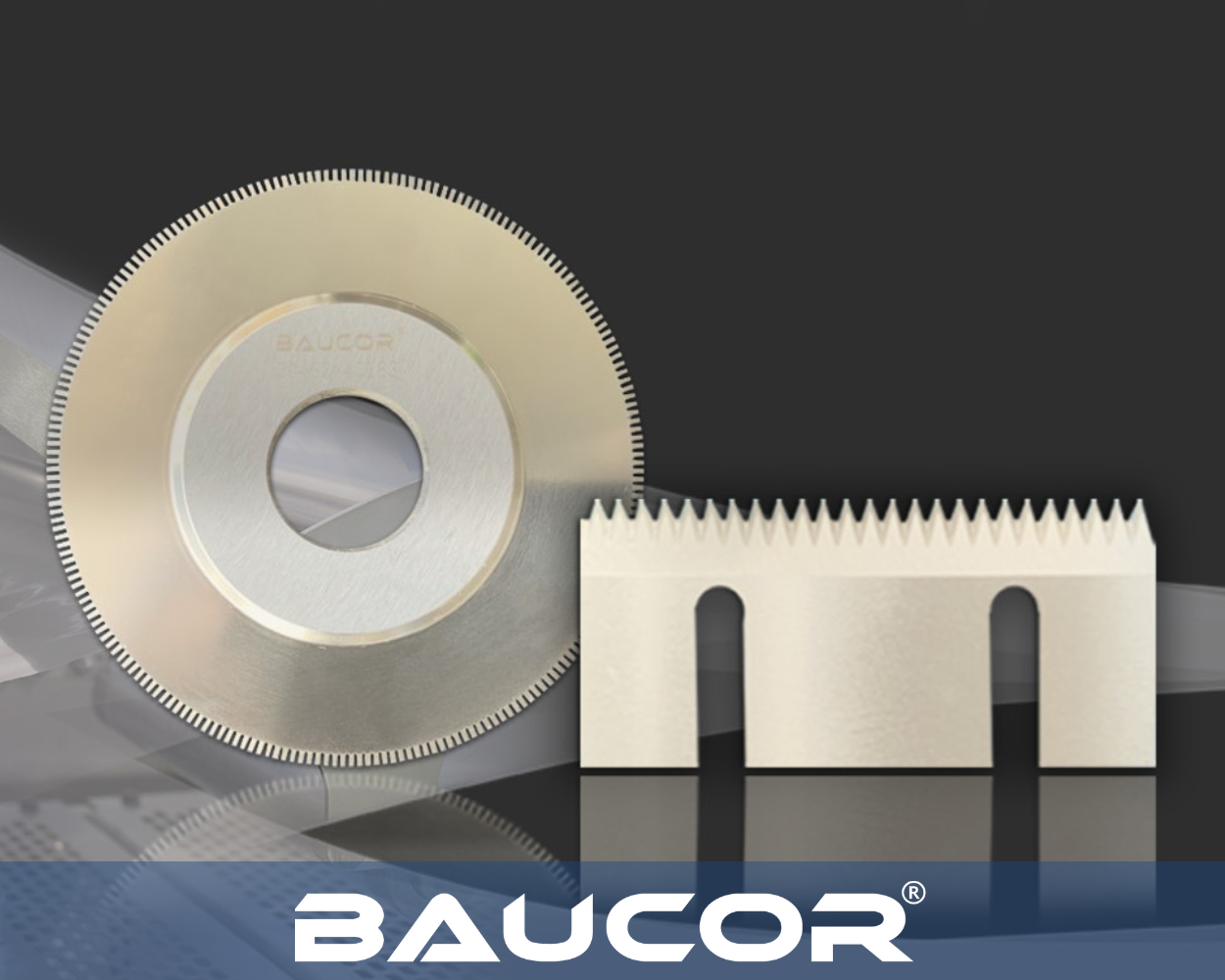

In terms of goods, Baucor provides a wide selection of blades for use in various sectors and applications. For every distinct need, Baucor has created a blade specifically made to cut through food items or cut paper. Their blades are renowned for their accuracy and robustness, guaranteeing effectiveness and extended performance.

Given their outstanding array of products and commitment to fine craftsmanship, it is hardly surprising that Baucor commands a significant share of the worldwide industrial blade market. Due to their standing as a reliable supplier of superior blades, they have gained recognition from clients worldwide.

GET A QUOTE

Challenges in the Industrial Blade Market

A. Technological advancements and their implications.

Technological advancements have revolutionised every industry, and the industrial blade market is no exception. Businesses in this sector face both opportunities and challenges from new technologies.

A significant consequence of technical advances is the necessity to upgrade machines. Businesses need cutting-edge equipment to compete as new technologies replace older ones. It is expensive and unprepared for by some companies.

Technology also changes client expectations. Consumers want blades with more precision, durability, and performance. Manufacturers must adjust their production techniques to accommodate these needs at competitive prices.

Automation in manufacturing processes also increases with technology. It increases productivity and lowers costs but may displace workers who need more skills to operate or maintain complex machinery.

Continuous innovation also means competitors continually try to outdo one other with new blade designs or materials. Companies must invest extensively in R&D to keep up with these rapid developments.

B. Rising material costs and supply chain complexities

Industrial blade manufacturers face rising material costs and complex supply chains. As technology and materials develop, blade raw material costs rise. That significantly raises production costs, making competing more challenging for enterprises.

In addition to growing material costs, supply chain complexity concerns enterprises. Organisations must navigate intricate foreign supply networks as global sourcing expands for blade materials. It typically requires dealing with international vendors, logistics providers, and customs rules.

Unexpected events like natural catastrophes or political instability can further disrupt the supply chain, causing delays and higher prices. Manufacturers must have contingency plans to reduce risks and maintain material flow.

Companies must optimise their supply chains and explore cheaper, equivalent materials to overcome these issues. Supplier collaboration is essential to developing new solutions to escalating material costs and supply chain complexity.

This dynamic market environment, where prices move swiftly owing to economic forces beyond control, requires quick adaptation. Businesses may overcome these hurdles and stay competitive in the industrial blade market by visiting updates about industry changes and aggressively exploring efficiency improvements throughout the value chain.

C. Diverse and evolving needs of different industries.

Meeting different industries' distinct and developing needs is difficult in the industrial blade industry. Packaging, food processing, and car manufacturing have additional cutting material requirements. Blade makers must constantly innovate and adjust their products to meet these changing demands.

In the packaging business, blades that can cut paperboard, plastic films, and corrugated cardboard cleanly at high speeds are in demand. Food processing requires sharp, corrosion-resistant, and contaminant-resistant blades.

Textile manufacturers need blades that can cut delicate materials without fraying. Automotive blades must endure hard cutting on metals and composites.

Blade makers must invest in R&D to tailor solutions for each sector to meet these unique needs. They must actively monitor industry advancements and work with customers to understand their needs to stay ahead of trends.

As demand fluctuates across industries, they need flexible production capabilities to modify their operations quickly. They invest in innovative machinery and automation to mass-produce blades with tight quality controls.

D. Environmental and regulatory challenges.

Environmental and regulatory issues are impacting the industrial blade market. Companies in this area are under pressure to go green due to sustainability and environmental concerns. That includes reducing waste energy use and following strict restrictions.

Ensuring manufacturing processes meet environmental criteria takes time and effort. Manufacturing industrial blades requires careful waste management, including correct disposal of hazardous materials. Implementing effective recycling programs helps lower the industry's ecological imprint.

Meeting tight government regulations is another issue. These restrictions set noise, pollution, and worker safety limits. Compliance with these laws assures legal compliance and boosts industry businesses' reputations.

Industrial blade producers operating internationally must also navigate complex international rules as businesses globalise. Maintaining seamless operations and compliance requires careful attention to country-specific product quality control and safety laws.

In addition to meeting environmental and regulatory requirements, the industrial blade market's success requires staying ahead of developments. Anticipating future developments lets organisations modify their tactics proactively rather than defensively to new rules.

Baucor's Strategies for Meeting These Challenges

A. Innovation and Research & Development (R&D) efforts.

Innovation and R&D solve Baucor's industrial blade market challenges. Baucor remains ahead of the curve by investing in new technology and developing innovative solutions to provide clients with cutting-edge blades that match their needs.

Baucor's engineers, scientists, and technicians push blade design and performance frontiers. They constantly enhance or create new items through considerable research and development.

Baucor makes precise, durable blades using innovative manufacturing methods such as precision grinding, laser cutting, EDM wire cutting, CNC machining, etc. This devotion to technology helps them compete in a fast-changing market.

Baucor also actively works with customers to understand their needs. This customer-centric strategy lets them customise blade systems for specific applications or industries. Baucor has accurate cutting tools for packing machines, food processing equipment, medical device manufacture, and other industries.

Baucors' investment in cutting-edge equipment and machinery boosts their ability to produce high-quality blades quickly. The organisation also ensures product quality with strict quality control requirements during production.

B. Adaptation to changing market demands.

Baucor has survived the fast-paced industrial blade market by adjusting to market demands. Keeping up with trends and outperforming the competition has required this technique.

Baucor excels in identifying new needs and promptly adjusting its production line. Baucor can adapt its products to changing market demands by continuously tracking customer preferences. Baucor can accommodate any material or design change.

Baucor invests heavily in R&D to ensure their blades are high-quality and meet industry standards. They create unique goods that meet customer needs by remaining current on technology.

Baucor also knows that meeting challenges requires vital customer service and unique goods. They seek client feedback and improvement through open communication channels. It lets them improve their products depending on real-time user feedback.

C.Investment in quality control and customer service

Baucor relies on quality control and customer service to overcome industrial blade market constraints. Baucor knows it must provide top-notch products and services to stay ahead in a competitive market with changing client needs.

Baucor invests considerably in quality control technologies and equipment to ensure high-quality blades. Industry regulations require rigorous testing of every blade. Baucor puts precision and accuracy first in material selection and manufacture.

Baucor also excels at customer service. The organisation believes long-term success requires solid customer relationships. They value quick communication, reaction times, and personalised service. Baucor exceeds client expectations in technical support and query resolution.

D. Partnerships and collaborations for technological advancements.

Baucor, an industrial blade market leader, knows that partnerships and collaborations are crucial to keeping ahead in today's fast-changing technology. Baucor stays ahead of the curve by collaborating with other industry leaders.

By collaborating with like-minded organisations, Baucor can use new ideas, experience, and resources to improve its products. Baucor has key collaborations to access cutting-edge machinery and technologies to make blades of unrivalled precision and quality.

Collaborations enable knowledge sharing and learning. By engaging with other industry leaders, Baucor stays current on trends and consumer needs. It allows them to adjust production methods and offer blades that exceed consumer expectations.

Baucor can incorporate new technologies into their products by cooperating with IT firms. These relationships help Baucor keep ahead of blade industry technology, from new materials to automated manufacturing.

Baucor maximises growth and product performance by forming strong ecosystem alliances. In an ever-changing market, these activities allow them to face obstacles and establish themselves as a trusted source of cutting-edge industrial blades.

GET A QUOTE

Future Outlook

Several significant developments will influence the direction of the industrial blade industry as we move to the future. Baucor is in an excellent position to set the standard because of its dedication to innovation and client pleasure.

The growing need for specialised blades for particular sectors and uses is one such trend. Blades that can adapt to the specific requirements of enterprises are necessary as technology develops and industries get more specialised. Because of their proficiency with customisation, Baucor can provide accurate solutions that maximise effectiveness and performance.

Another significant trend is the increasing emphasis on sustainability and environmentally friendly practices across businesses. Companies are looking for blades made from sustainable materials or built for longer endurance, decreasing waste, as environmental concerns become increasingly important.

Additionally, as automation transforms industrial processes, there will be a greater need for precision cutting instruments. Recognising this trend, Baucor invests in cutting-edge equipment and technology to create the exact blades needed by automated systems.

Baucor remains committed to industry innovation in its future objectives. They consistently invest in R&D projects to enhance blade performance while guaranteeing their clients' cost-effectiveness.

Additionally, Baucor wants to increase its global footprint by forming strategic alliances with distributors around the globe. They can efficiently reach new markets and provide localised support with this expansion plan.

In terms of predictions for both the industry and Baucor's role, we foresee continued growth driven by technological advancements across various sectors such as packaging, food processing, medical devices, plastics recycling, and automotive manufacturing - just to name a few! Baucor has an opportunity to influence the industrial blade industry as a supplier and influencer amid these exciting changes.

Conclusion

In summary, Baucor has positioned itself strategically in the industrial blade market by continuously embracing innovation, adjusting to shifts in the industry, and putting the needs of its customers first. Its dedication to quality and wide range of products highlights the company's tenacity in conquering obstacles. Baucor creates the foundation for long-term success with its proactive approach to technology developments and, when appropriate, strategic expansion projects. As a dependable and creative participant in the market, Baucor is positioned for sustained growth and contributions, positioning it as a significant competitor in the changing industrial blade landscape.

English

English