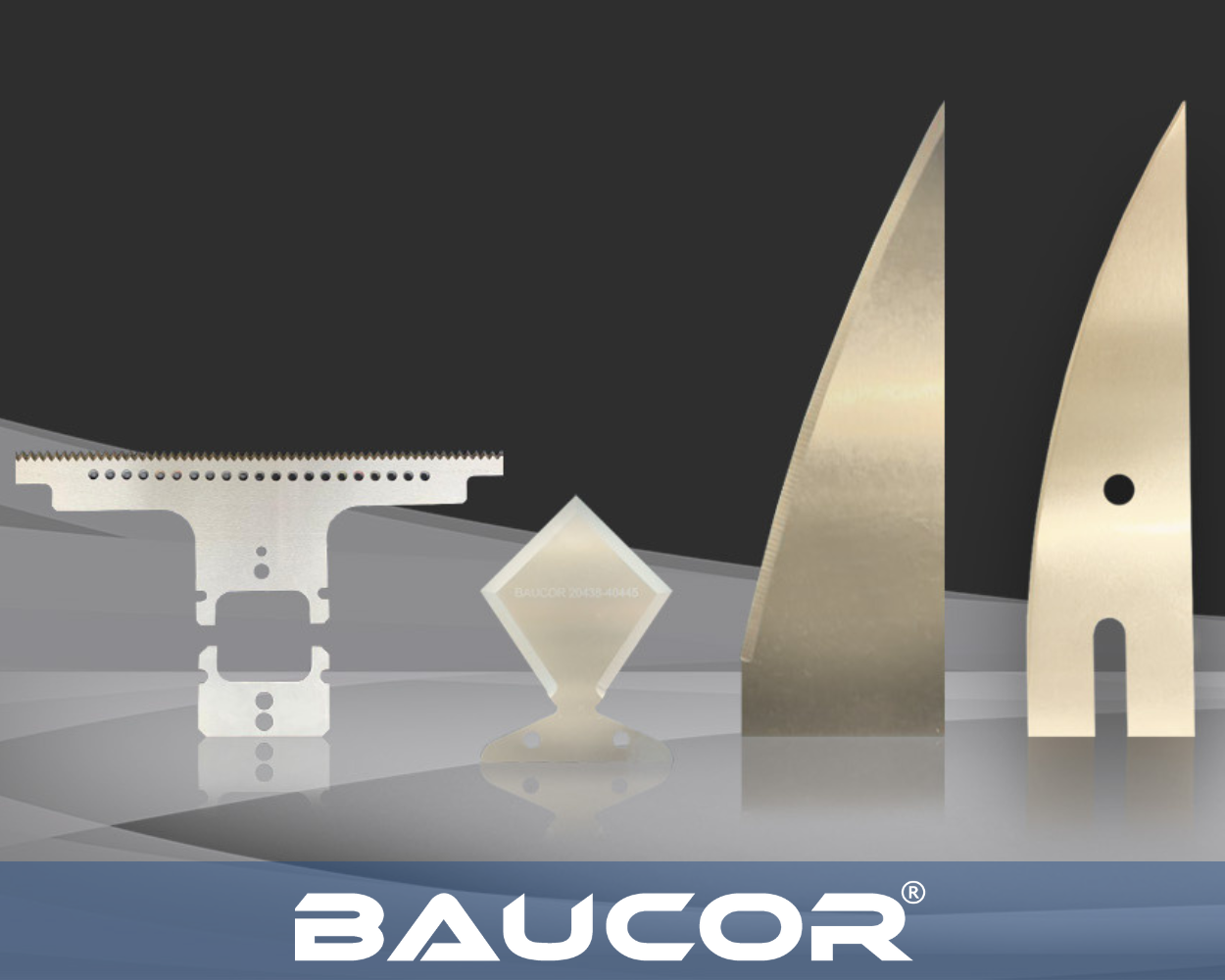

The Art of Custom Machine Knife Manufacturing: BAUCOR's Tailored Solutions for Packaging, Food, Plastic, Tire, and Rubber Industries

In the intricate world of industrial manufacturing, one size rarely fits all. Each industry, each application, and each material demands a unique cutting solution. This is where custom machine knives shine, and BAUCOR is leading the charge in providing tailored solutions for packaging, food, plastic, tire, and rubber industries.

The Power of Customization

Custom machine knives are not just tools; they are precision instruments meticulously crafted to match the exact requirements of a specific process. This level of customization offers several key advantages:

- Optimal Performance: Custom knives are designed to maximize efficiency, productivity, and quality in a given application. They are engineered to cut specific materials with the ideal geometry, edge profile, and hardness.

- Reduced Downtime: Tailored knives often outlast standard options, minimizing the need for frequent replacements and reducing costly downtime.

- Enhanced Safety: Custom designs can incorporate safety features that minimize the risk of accidents and injuries, protecting both workers and the integrity of the final product.

- Material Versatility: Whether you're cutting through delicate packaging films, tough rubber compounds, or abrasive plastics, a custom knife can be engineered to handle the specific material challenges.

BAUCOR: Your Partner in Precision

BAUCOR's expertise in custom machine knife manufacturing stems from their commitment to innovation, quality, and collaboration. They work closely with clients to understand their unique needs and challenges, then leverage their engineering prowess to deliver tailored solutions that exceed expectations.

Here's how BAUCOR contributes to the world of custom machine knives:

- In-Depth Consultation: BAUCOR's experts engage in thorough discussions with clients to gather detailed information about their processes, materials, and desired outcomes.

- Advanced Engineering: BAUCOR's engineers utilize state-of-the-art CAD software and simulation tools to design knives that perfectly match the client's specifications.

- Material Selection: BAUCOR carefully selects the optimal materials for each application, considering factors like hardness, wear resistance, corrosion resistance, and overall durability.

- Precision Manufacturing: BAUCOR employs advanced CNC machining, grinding, and heat treatment processes to fabricate knives with exceptional precision and consistency.

- Rigorous Testing: Each custom knife undergoes stringent quality control checks to ensure it meets or exceeds the client's performance expectations.

BAUCOR's Industry-Specific Solutions

BAUCOR's custom machine knives find applications across a wide spectrum of industries:

- Packaging: Slitting, perforating, and sealing knives for various packaging materials.

- Food: Knives for slicing, dicing, and portioning meat, poultry, fish, fruits, and vegetables.

- Plastic: Cutting blades for films, sheets, and profiles.

- Tire: Knives for cutting rubber compounds and shaping tire treads.

- Rubber: Slitting and trimming knives for rubber products.

GET A QUOTE

BAUCOR's Commitment to Sustainability

BAUCOR recognizes the importance of sustainable manufacturing. They strive to minimize waste, conserve resources, and reduce their environmental impact throughout the production process.

Conclusion

In the world of industrial manufacturing, where precision, efficiency, and safety are paramount, custom machine knives are indispensable tools. BAUCOR's dedication to innovation, quality, and collaboration makes them the ideal partner for businesses seeking tailored solutions that optimize their cutting processes.

Whether you're in the packaging, food, plastic, tire, or rubber industry, BAUCOR has the expertise and capabilities to deliver custom machine knives that meet your exact needs and elevate your production to the next level.

English

English