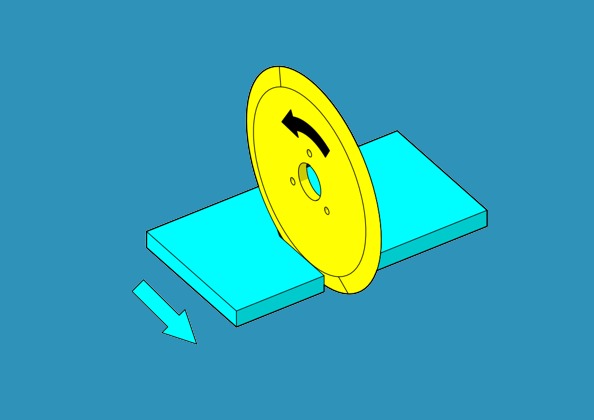

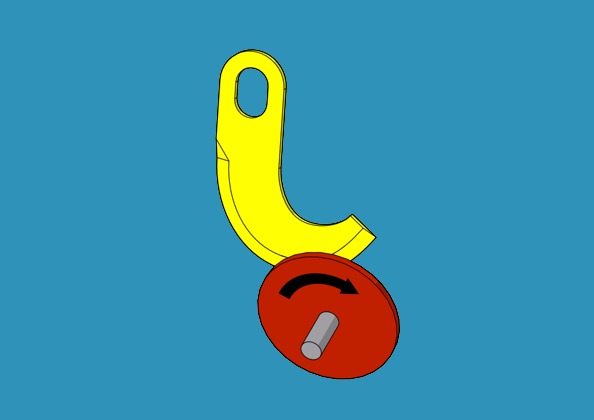

Scoring blades, also known as creasing blades, are used to create a shallow cut or indentation in a material. The purpose of a scoring blade is to weaken the material along a specific line, making it easier to fold or bend along that line without tearing or damaging the material.

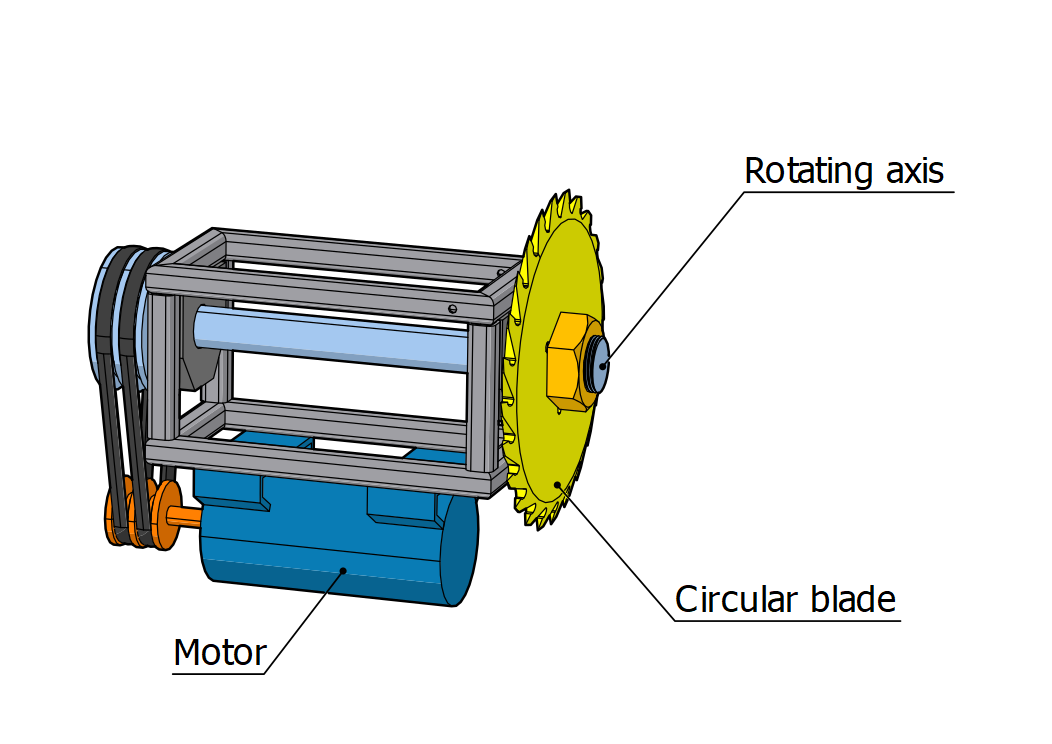

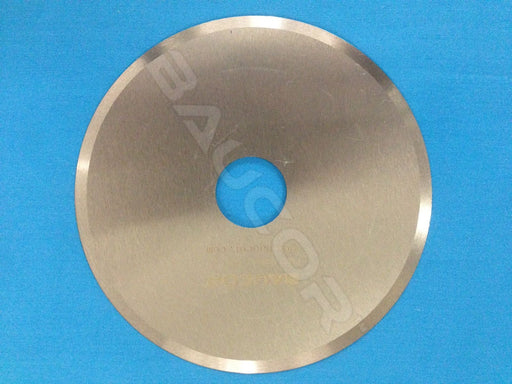

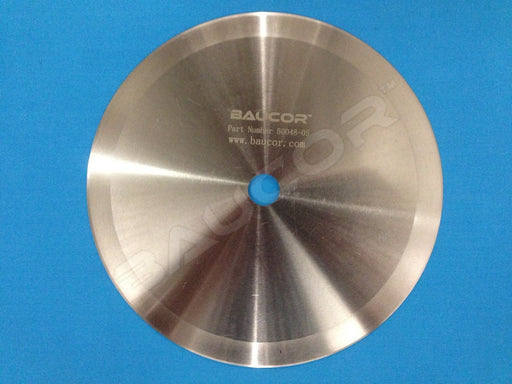

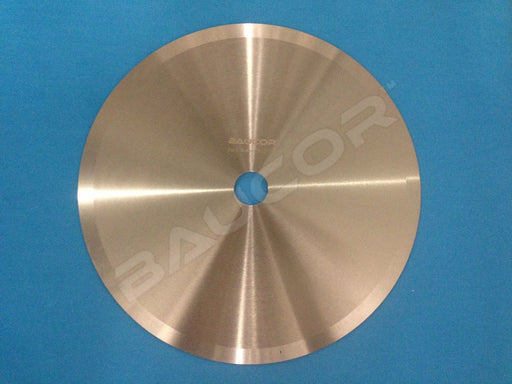

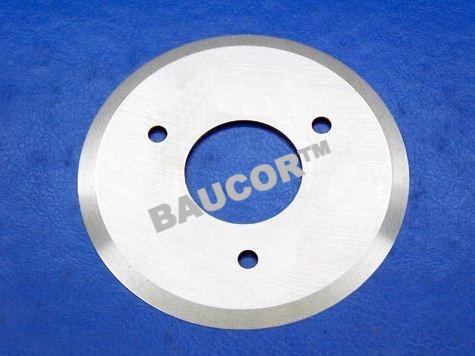

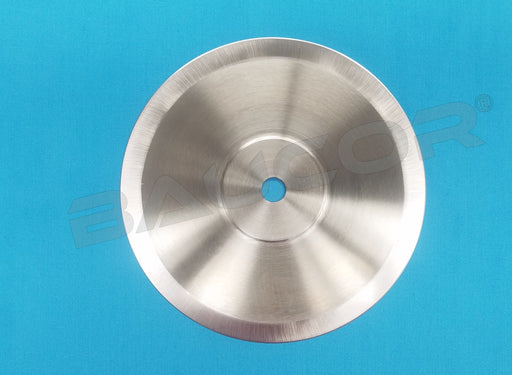

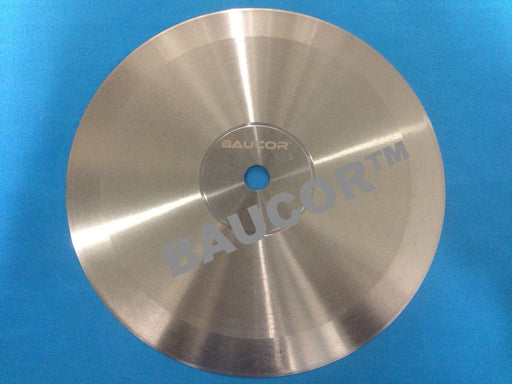

Scoring blades are typically circular blades made of high-carbon steel. They are commonly used in the printing and packaging industry to create precise, clean folds in thin materials such as paper and cardboard products, such as boxes, cartons, and brochures.

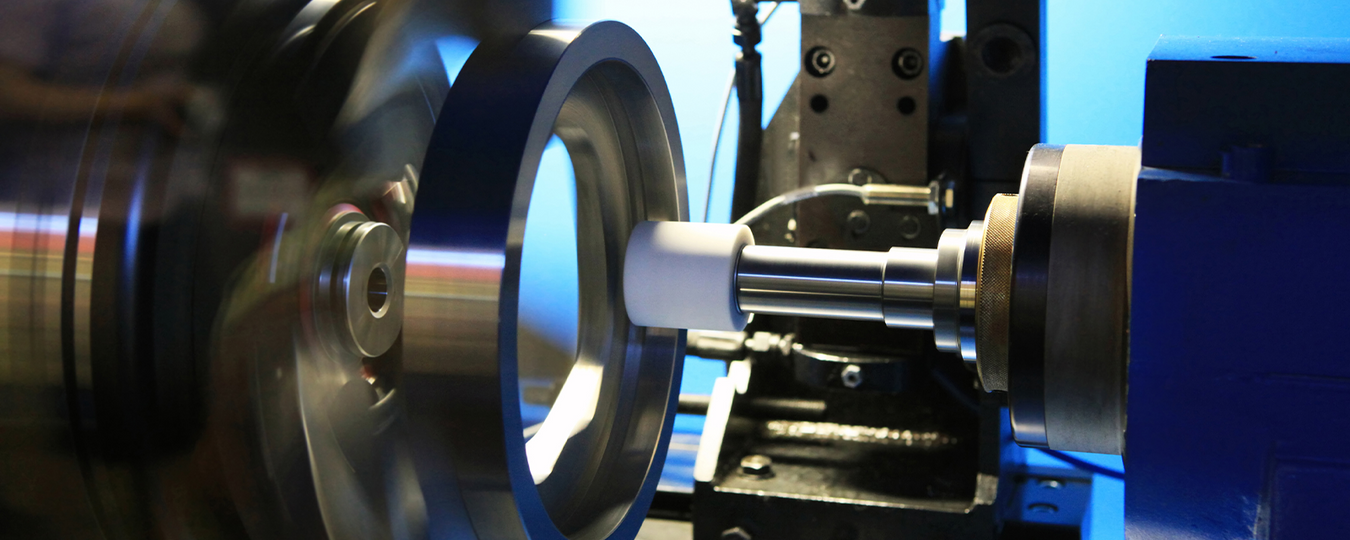

If precision, quality and short lead time all matter, you are at the right place. Baucor manufactures and supplies literally thousands of both precision standard and custom size score slitter knives and blades for all kinds of use. Whether it's paper cutting, packaging, rubber converting, film cutting or foil converting, regardless of what it's used for, our score slitter knives and blades are exceptionally made from quality ground hardened tool steels and stainless steel as well as carbide.

English

English