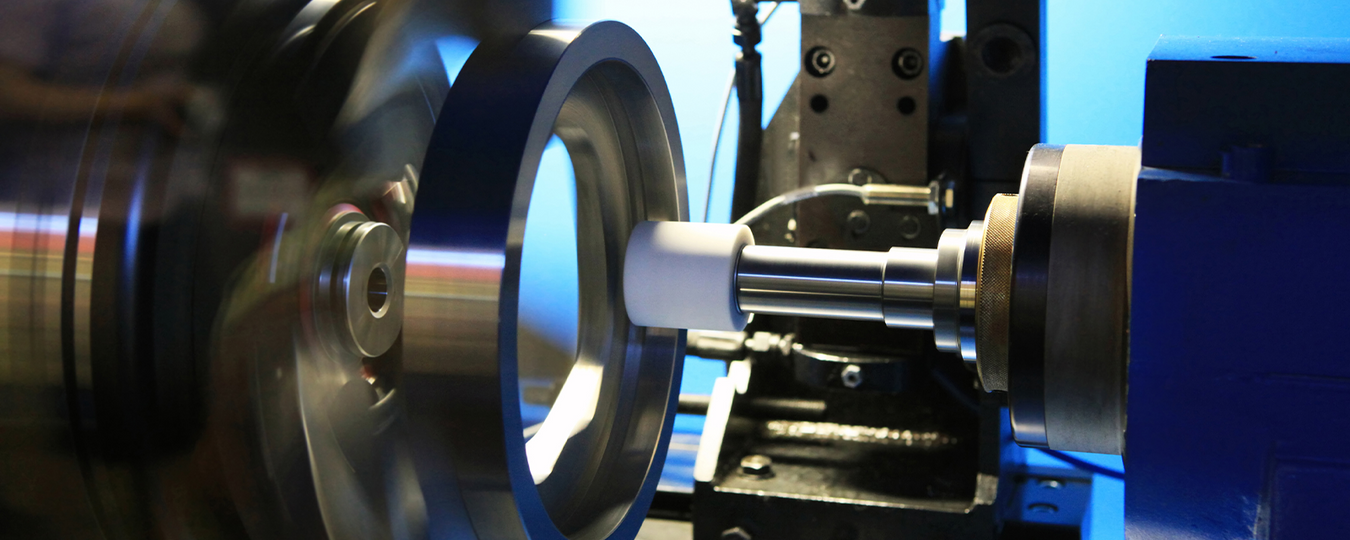

Poultry cutting blades are used for cutting operations such as chopping, peeling, slicing, dicing, and, even cleaning poultry like hen. Because of its manufacturing nature, poultry processing industry requires a steady push for premium quality poultry blades and vent cutter knives always delivered within the quickest turnaround time in the market. As a leading manufacturer and supplier of high quality poultry processing knives and vent cutter blades, Baucor has become one of the most trusted and reliable manufacturers of these cutting blades for the poultry industry. At our high-end facility, Baucor manufactures and stocks all kinds of poultry processing knives & vent cutters including top brands like Stork, Meyn, Marel, Linco and Systemate.

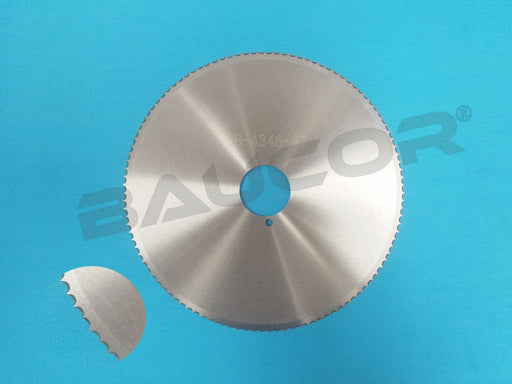

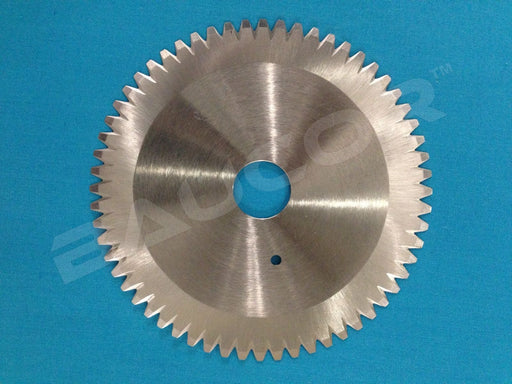

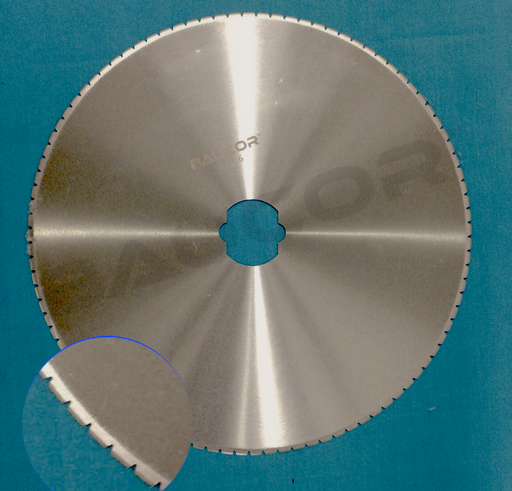

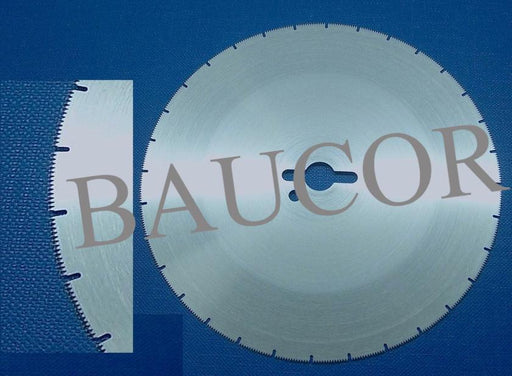

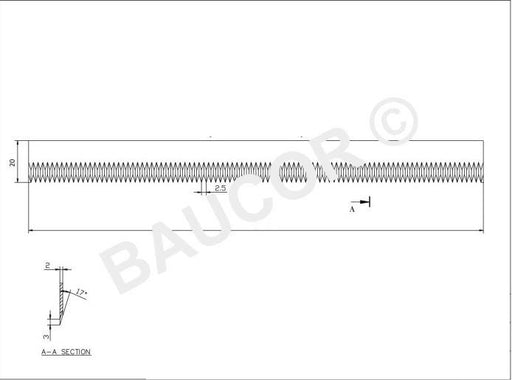

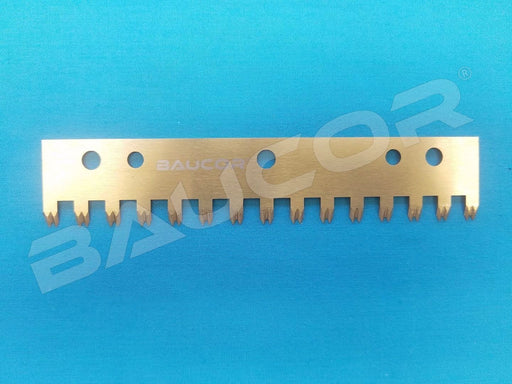

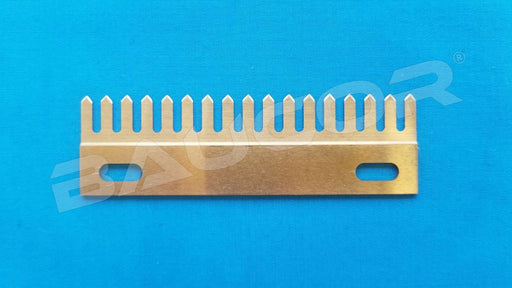

Baucor manufactures precision quality custom and standard size poultry processing knives and blades from high grade ground hardened stainless steels for poultry processing industries. Our poultry processing knives and vent cutters for poultry processing industry are in straight, circular, pointed tip, toothed, serrated, scalloped, perforated and many other blades by shapes.

English

English