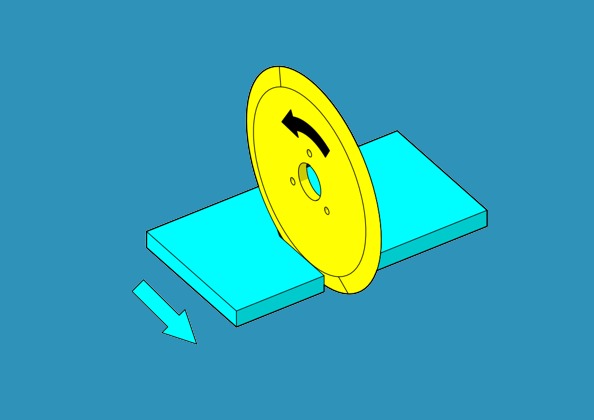

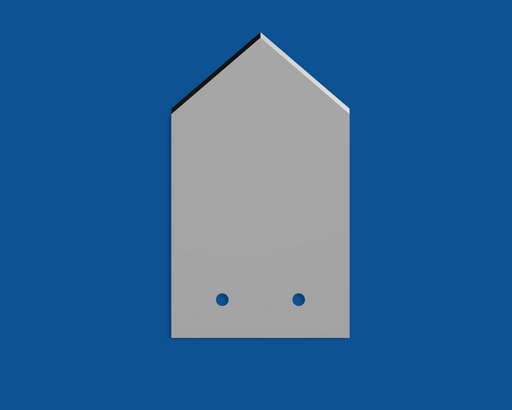

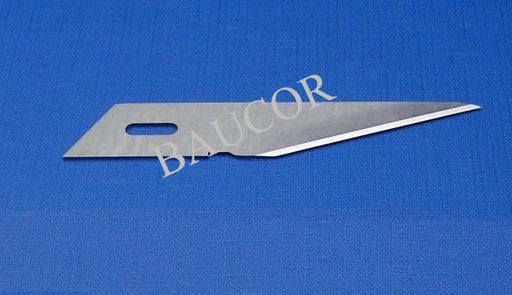

Plastic cutting blades are used for converting plastic material. Plastic cutting knives are used for cutting, slicing, slitting, peeling, chopping, perforating.

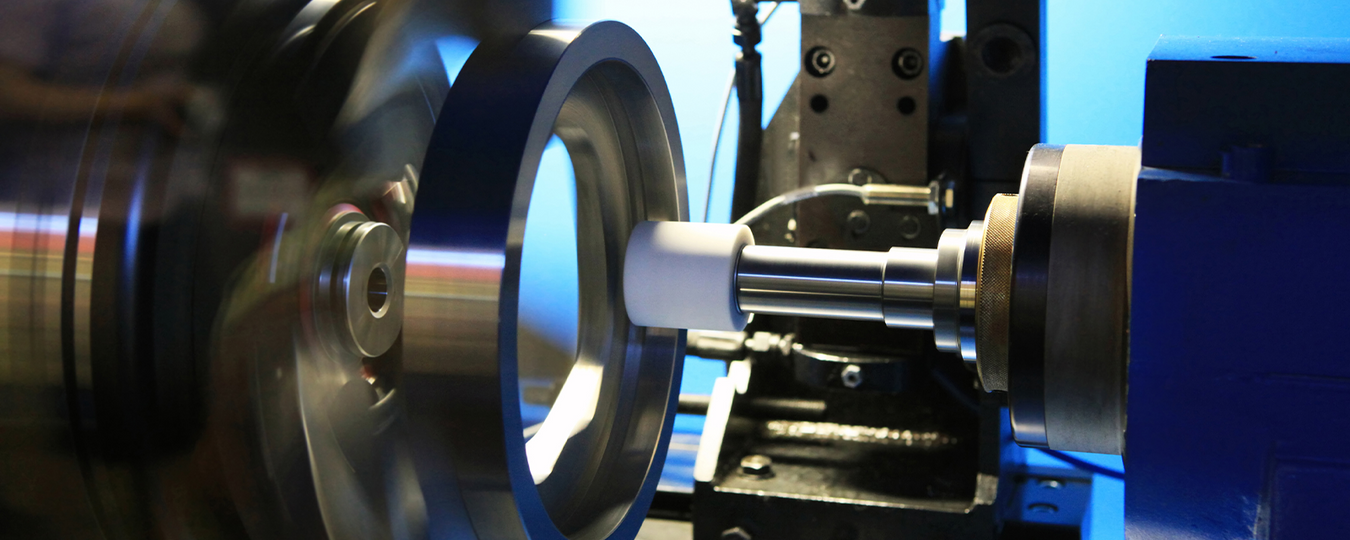

If you're looking for a reliable supplier that manufactures only the highest quality razor sharp plastic cutting knives and blades for plastic industry, you are at the right place. Custom and standard size plastic cutting knives made from premium quality hardened tool steels and fine grade stainless steels are one of our specialties at Baucor.

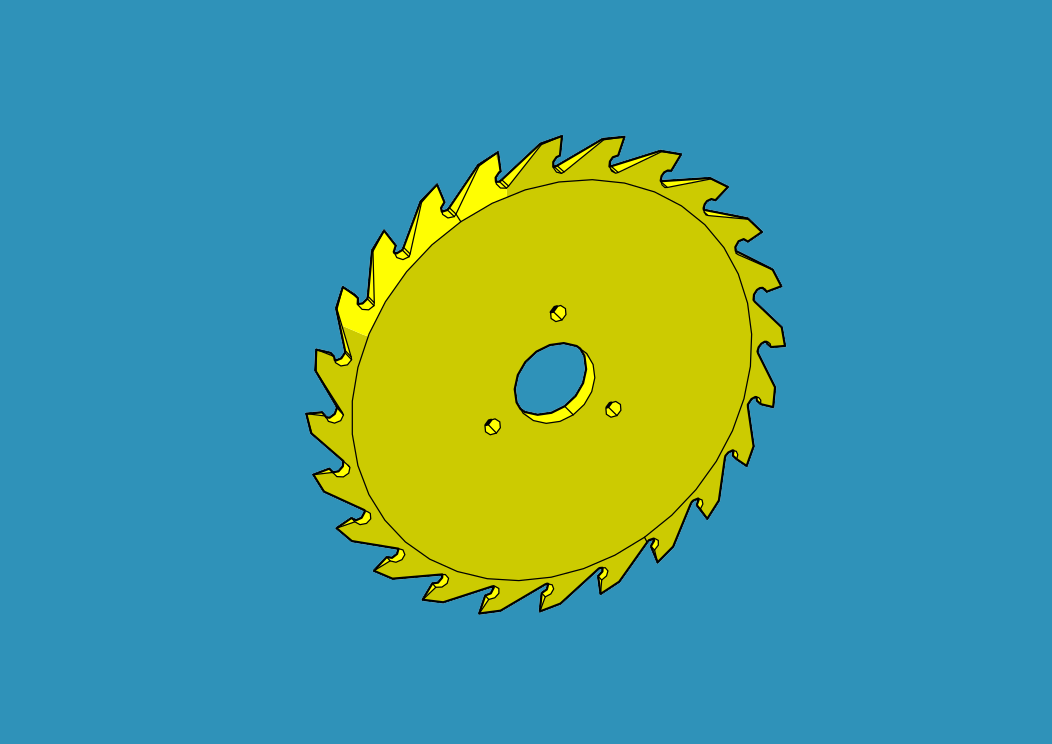

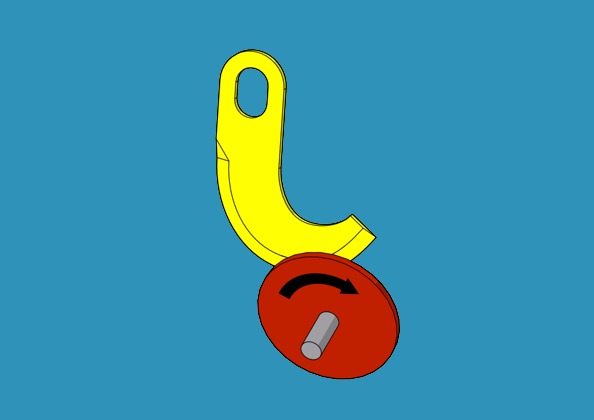

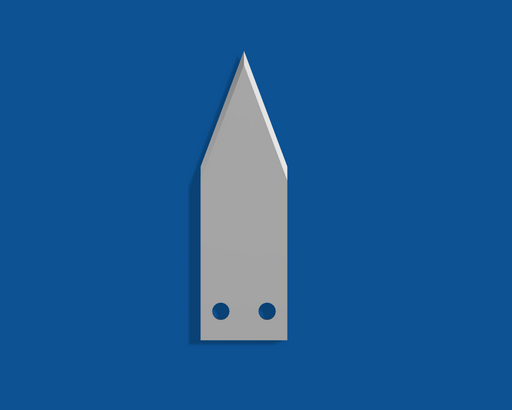

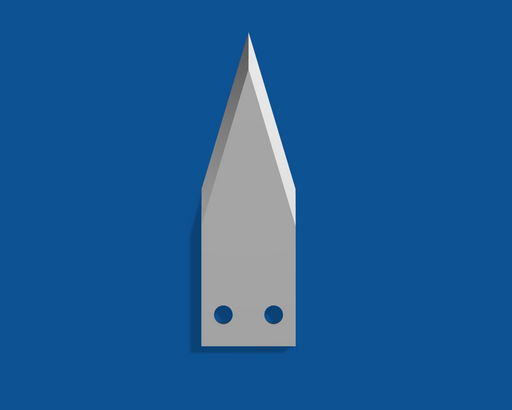

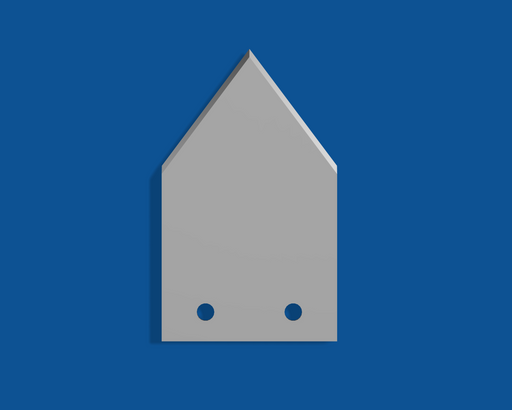

We manufacture plastic cutting knives and blades for many plastic industries including fresh and dry food packaging, medical packaging, polyethylene plastic bag manufacturing, film converting, plastic vinyl and foil converters and many others. Some of our packaging knife applications include perforating, guillotine cutting, rewinding, cut off, cross cut, horizontal and vertical cut and other packaging cutting applications. Our plastic cutting knives and industrial plastic blades are in straight, circular, pointed tip, toothed, serrated, scalloped and many other blades by shapes.

English

English