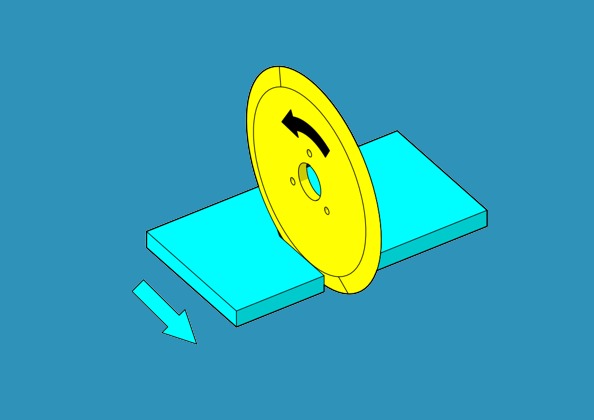

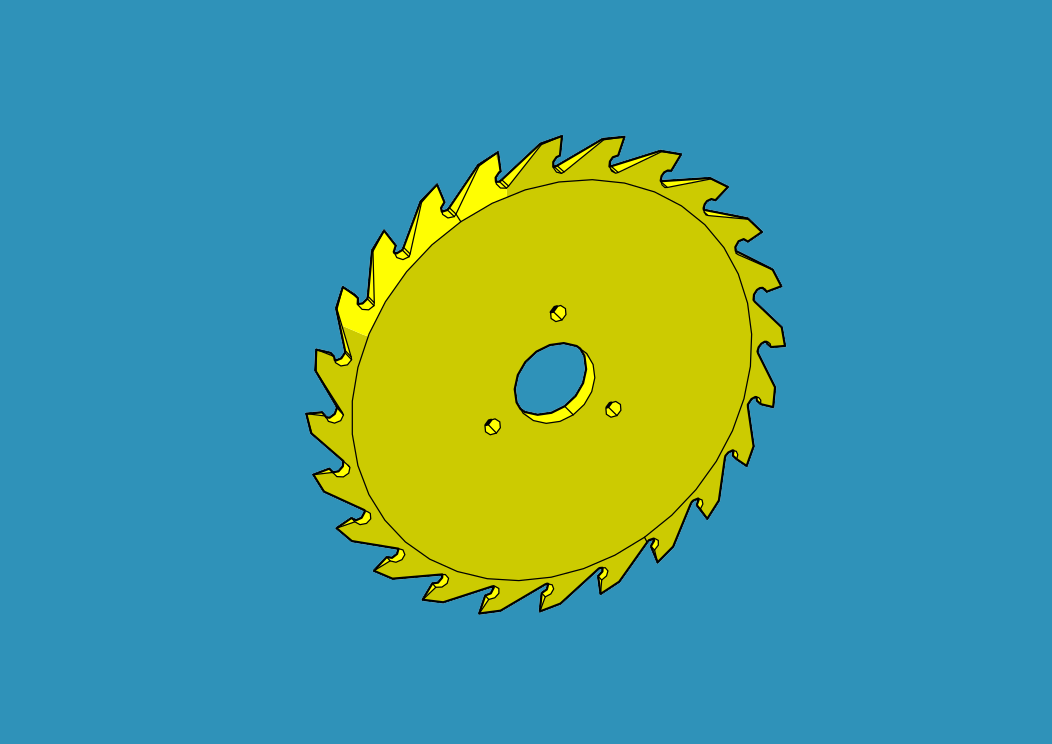

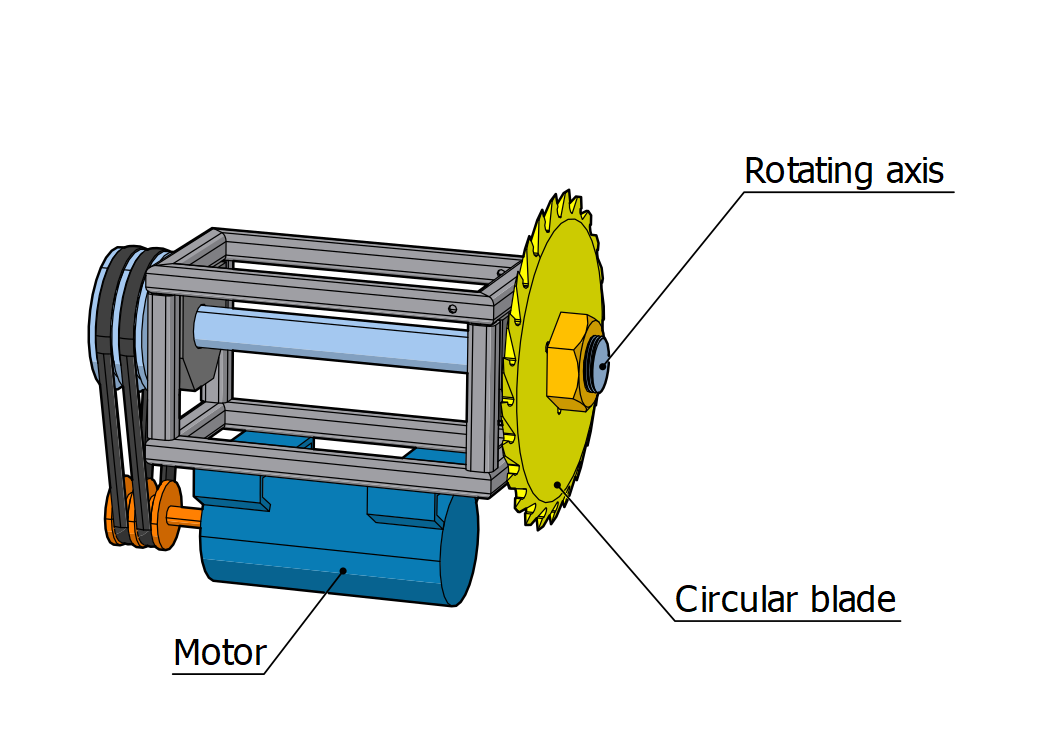

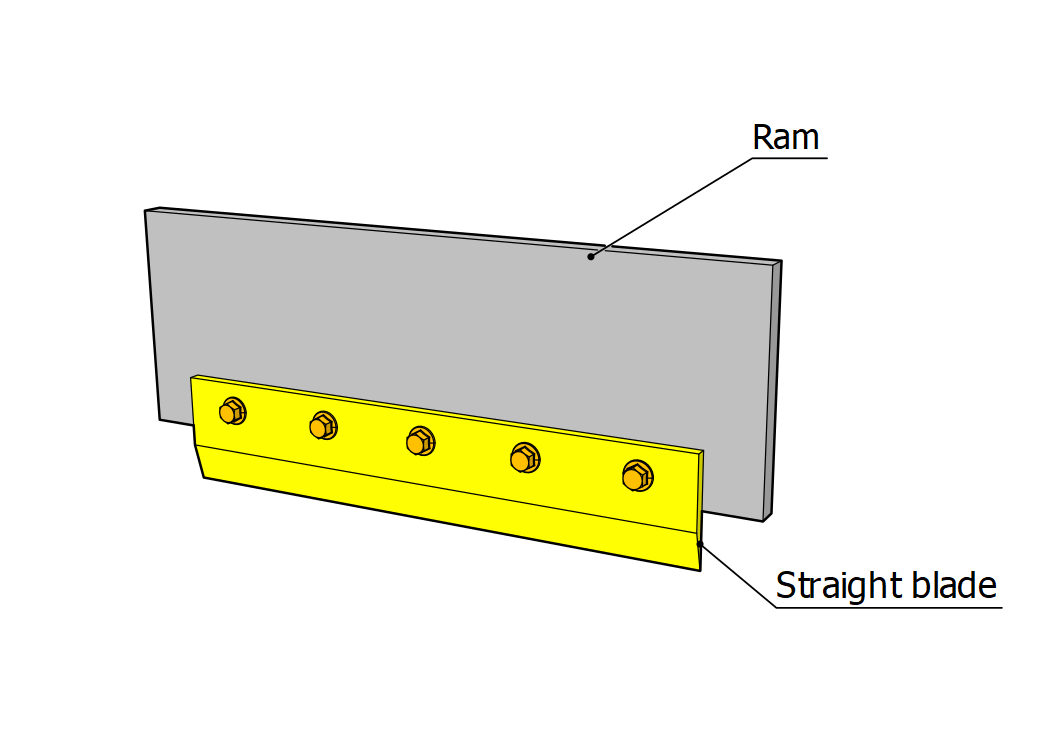

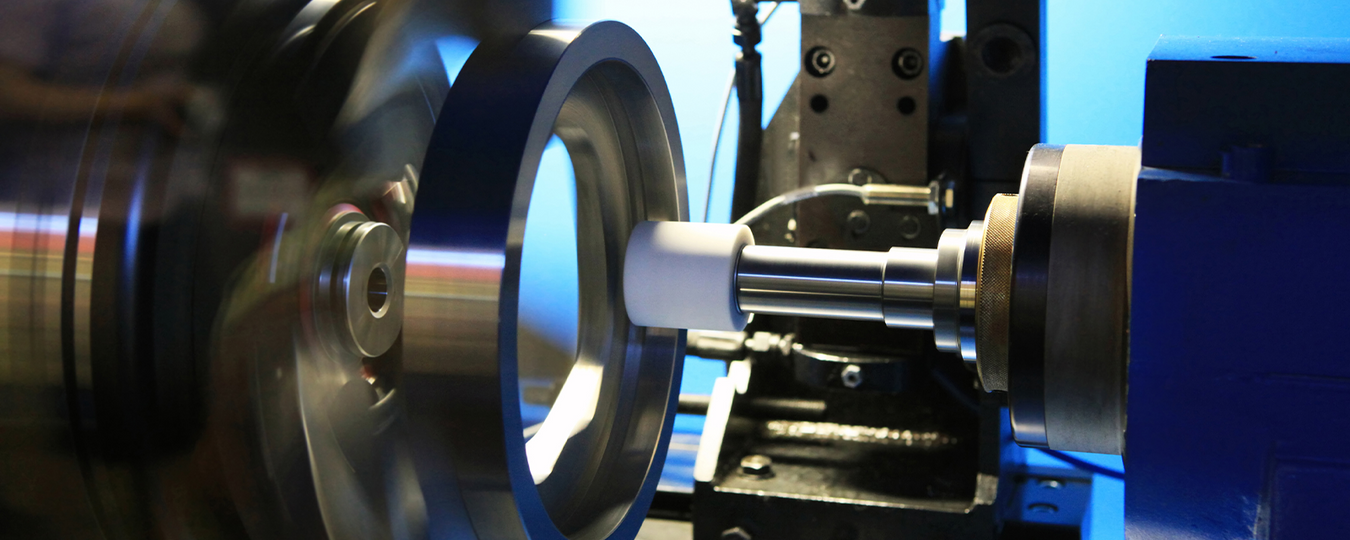

Perforating blades, also known as hole saws, are power saws used to create holes in wood, metal, plastic, and other materials.

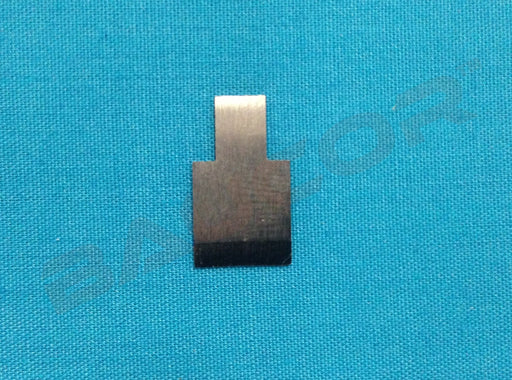

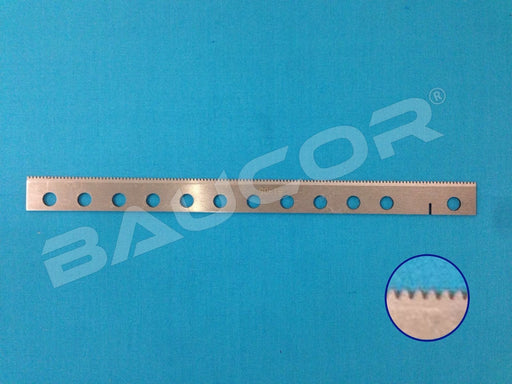

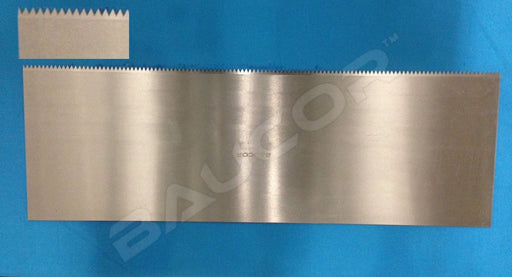

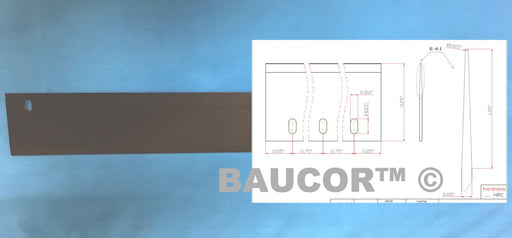

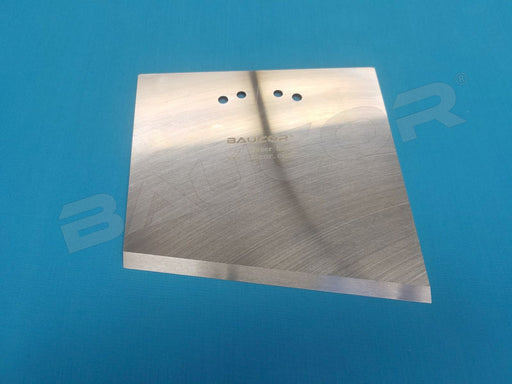

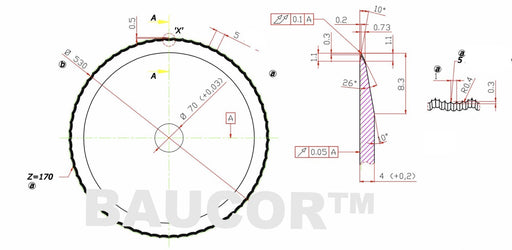

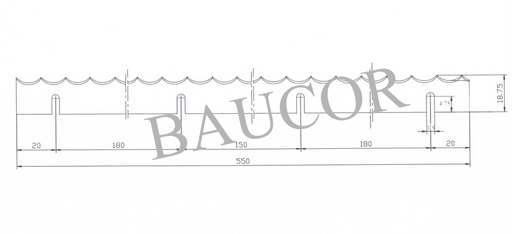

Perforating blades are made from various materials, including high-speed steel and tungsten carbide. We offer a wide range of perforating, from small blades that can cut holes in thin materials to large blades that can cut through thick materials. The size of the blade needed will depend on the application.

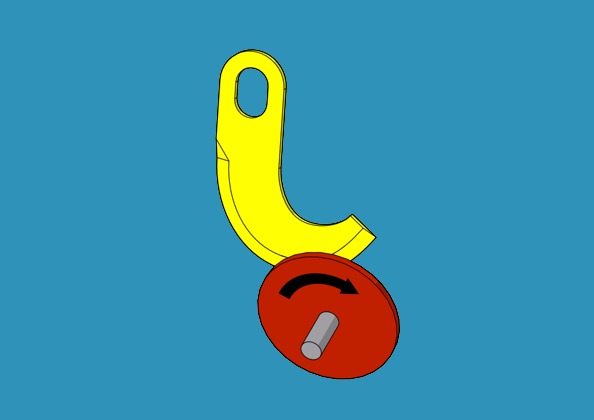

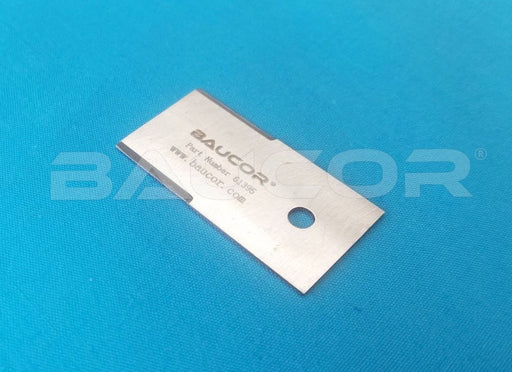

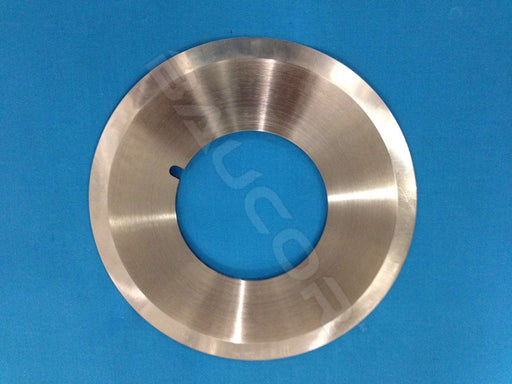

Baucor manufactures and supplies literally thousands of both standard and custom size precision perforating knife blades and perforator (perforation) blades in straight and circular shapes. Whether you need perforating blade with toothed, serrated, scalloped, perforation and saw tooth forms, or even more complex tooth forms, Baucor can turn your design into perforating knife blades and perforator (perforation) blades in just days. It doesn't matter if it's paper cutting, food slicing, packaging, rubber converting, meat chopping, film cutting or foil converting, regardless of its use, our circular knives and blades are exceptionally made from quality ground hardened tool steels and stainless steel as well as carbide.

English

English