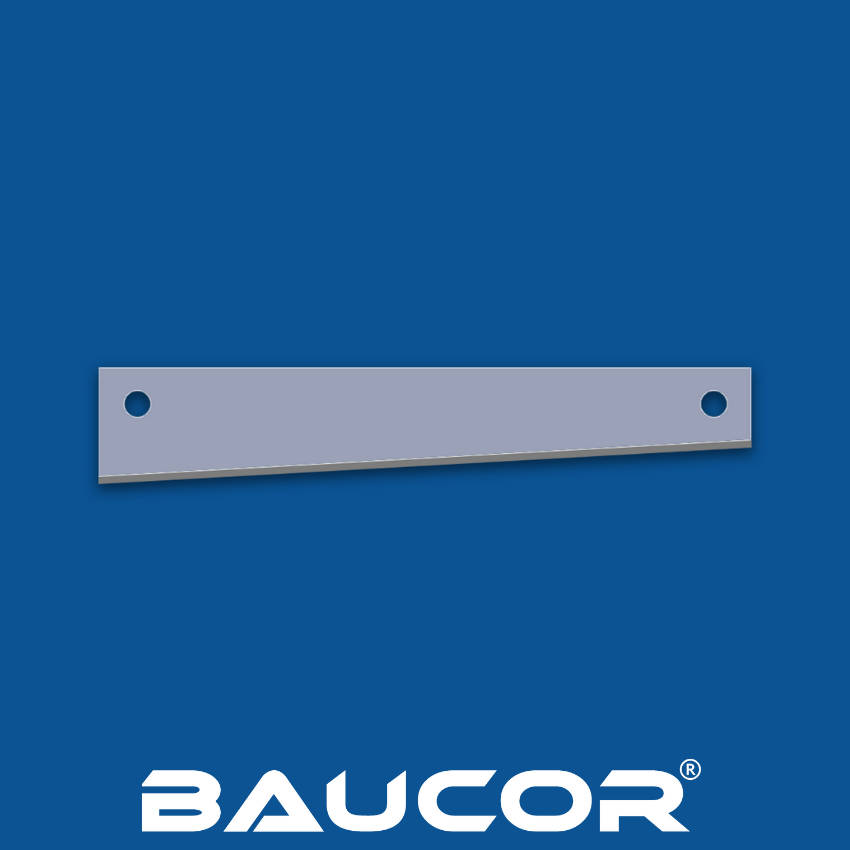

Paper-cutting blades are one of the essential tools in the paper-cutting industry. They are used in various paper-cutting machines and equipment, such as slitting machines, die-cutting machines, and laminators.

Paper cutting blades can be made from various materials, including stainless steel, carbon steel, and tungsten carbide, and are designed to be sharp and durable to ensure precise cuts and long service life.

If you're looking for a reliable supplier that manufactures only the highest quality razor sharp paper cutting knives and paper cutting blades for paper and packaging finishing and converting applications, then you are at the right place. Precision quality custom and standard size paper cutting blades and knives made from premium quality hardened tool steels, as well as tungsten carbide are one of our specialties at Baucor. We manufacture custom made and off-the-shelf size paper cutting knives and blades for most paper converting applications including perforating, guillotine cutting, rewinding and cut off. Our machine knives and industrial blades for paper cutting and trimming are in straight, circular, pointed tip, toothed, serrated, scalloped, perforated and many other shapes.ten specifications for the blade you need, please let us know.

English

English