Industrial Carbide Blades and Knives and BAUCOR’s capabilities

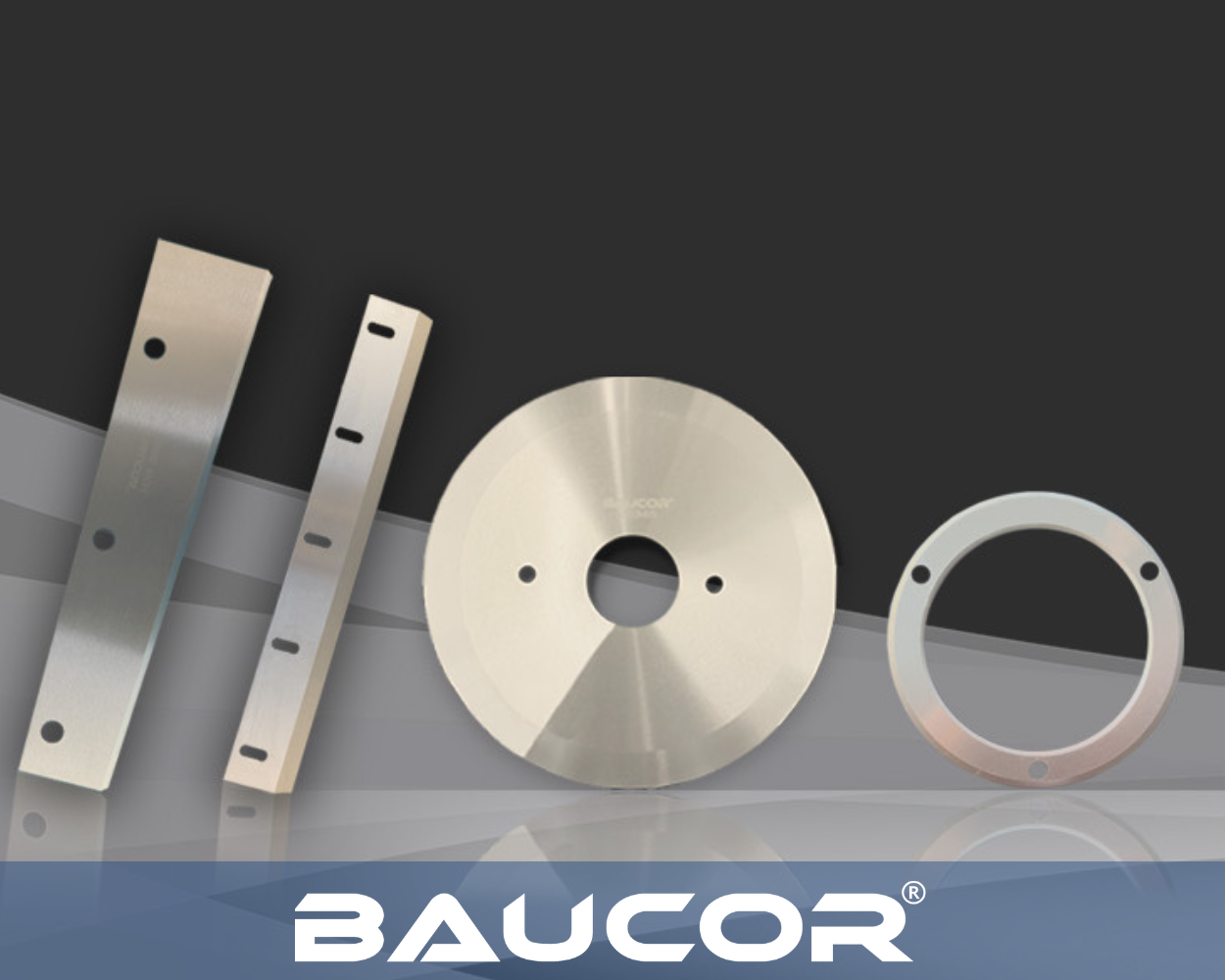

Industrial Carbide Blades and Industrial Carbide Knives are crucial in various industries, such as packaging, printing, food processing, plastics, etc. BAUCOR's capabilities to manufacture high-quality industrial carbide blades and knives make it a trusted partner for businesses looking for precision cutting solutions.

With its expertise in custom blade design and manufacturing, BAUCOR ensures that each blade meets the unique requirements of its clients. Whether you need standard or custom industrial carbide blades or knives, BAUCOR has the knowledge and experience to deliver top-notch products that exceed expectations. Choose BAUCOR for all your industrial cutting needs and experience the difference quality makes!

What Sets BAUCOR Apart from Other Industrial Blade Manufacturers?

Several key features set BAUCOR apart from its competitors in the business and make it a leading maker of industrial blades.

Above all, there is nothing like BAUCOR's dedication to quality. The company uses state-of-the-art technology, precision engineering, and strict manufacturing requirements to create incredibly durable and sharp blades. Because of its commitment to quality control, BAUCOR's blades constantly meet and exceed the expectations of its wide range of customers.

Another noteworthy feature distinguishing BAUCOR is its focus on tungsten carbide knives and blades. The base material of cutting tools made by BAUCOR is tungsten carbide, renowned for its toughness and resistance to wear. Because of its material expertise, the company can offer customers blades with longer lifespans, a cost-effective answer for their cutting demands.

Customization is a defining feature of the BAUCOR method. The business works closely with customers to comprehend their particular needs and difficulties. Because of its commitment to customers' needs, BAUCOR can create custom blades suited for particular uses and provide the best possible results in various industrial environments.

In addition, BAUCOR's leadership position in the industry results from its flexibility and responsiveness in adjusting to market trends and technical developments. By consistently improving its manufacturing methods, the company keeps ahead of the curve and provides cutting-edge solutions that meet the changing demands of contemporary industries.

Essentially, BAUCOR's unwavering quality standards, tungsten carbide knowledge, customization commitment, and flexibility to changes in the industry strengthen its position as a top choice for companies looking for superior industrial blades.

Quality and Durability of Industrial Carbide Blades and Knives from BAUCOR

Industrial carbide blades and knives from BAUCOR are known for their high quality and long lifespan, which is evidence of the company's persistent dedication to perfection. Because of its reputation for manufacturing cutting tools that continuously satisfy the highest industry requirements, BAUCOR is known as a dependable and trustworthy supplier.

Careful material selection is one of the main elements influencing the exceptional quality of BAUCOR's industrial carbide blades. The core of these blades is made of tungsten carbide, a strong and incredibly durable substance.

Compared to traditional steel blades, this option guarantees unmatched strength, resistance to wear, and an extended operational life. Adding tungsten carbide to BAUCOR's blades improves their overall performance, making them perfect for demanding industrial applications.

BAUCOR uses modern manufacturing techniques and technology to create accurate and precise blades. The production cycle uses advanced machinery and quality control to ensure each blade matches the company's strict standards. This commitment to accuracy lowers the need for maintenance and replacements of the blades over time while ensuring consistent cutting performance.

Industrial carbide blades from BAUCOR are known for their durability. These instruments are made to endure the demanding use in various heavy-duty cutting applications. End users can save money with BAUCOR's blades because they are resilient and stay sharp for extended periods, even in demanding situations like metalworking and plastic processing.

Specialized Capabilities of BAUCOR in Manufacturing Industrial Carbide Blades and Knives

Regarding production, BAUCOR stands out because it makes industrial carbide blades and knives very well. The business has refined its knowledge to provide innovative solutions for different sectors' complex and demanding requirements.

A key component of BAUCOR's specialized skills is its expertise with tungsten carbide. Industrial blade manufacture requires tungsten carbide, and BAUCOR is an expert at utilizing its unique qualities for the best results. The hardness, endurance, and wear resistance of tungsten carbide blades make them better than traditional materials for demanding cutting tasks.

An additional feature that makes BAUCOR unique is customization. The business is aware that various applications and industries have various cutting needs. To resolve this, BAUCOR works closely with clients to comprehend their unique requirements and difficulties. Because of its customer-first philosophy, BAUCOR can create knives and carbide blades that match the unique requirements of specific cutting jobs. BAUCOR's customization capacity makes its blades ideal for medical device manufacture and automobile cutting.

Moreover, BAUCOR uses cutting-edge technology and contemporary manufacturing methods to keep a competitive edge in the market. Thanks to its cutting-edge machinery and facilities, the company can produce precision blades with strict tolerances. Technological innovation improves BAUCOR's products and ensures blades fulfill industrial cutting efficiency and precision criteria.

GET A QUOTE

The Process of Manufacturing Industrial Carbide Blades and Knives

Industrial carbide blade and knife manufacturing is a painstaking process that calls for accuracy and knowledge. The first step in the process at BAUCOR is the selection of premium raw materials to guarantee performance and durability. The required blade or knife design is then achieved by carefully shaping and cutting the material with cutting-edge technology.

The knives or blades then undergo a thorough heat treatment, increasing their strength and hardness. This stage is essential to guarantee that the finished product can endure harsh environments and keep its edge long.

Then, with great attention to detail, the knowledgeable specialists at BAUCOR carefully grind and sharpen every blade or knife to perfection, ensuring accurate cutting outcomes. Before the items are prepared for delivery, quality inspections are carried out at every production stage to maintain the highest standards.

As a leader in the sector, BAUCOR is distinguished by its unwavering dedication to producing superior-quality industrial carbide blades and knives.

Industrial Carbide Blades and Knives Benefits in Different Industries

Industrial carbide blades and knives have revolutionized cutting processes and offered many benefits, making them essential instruments in various industries. Using these state-of-the-art instruments has several benefits, including improved precision and durability. The following are the top five advantages of using industrial knives and carbide blades in a variety of industrial applications:

Exceptional Durability and Longevity:

Tungsten carbide, well-known for its remarkable hardness and wear resistance, makes industrial carbide blades and knives. Because of their innate toughness, carbide blades considerably outlive conventional steel blades.

Tungsten carbide's toughness ensures that these blades stay sharp for extended periods, lowering the need for replacements. Because of their longer lifespan, industries benefit from increased operational efficiency, lower maintenance costs, and fewer downtime.

Versatility Across Industries

The adaptability of industrial carbide blades is one of their best qualities. These blades are used in many industries, including food production, textiles, plastics processing, and metallurgy.

Carbide blades are the perfect choice for sectors with various cutting requirements since they can precisely cut through various materials. Because they may use the same blade for various applications, this adaptability streamlines procedures and lowers complexity for companies operating in several industries.

GET A QUOTE

Precision Cutting for Enhanced Quality

Tungsten carbide blades provide remarkable cutting precision because of their hardness and sharpness. The precision carbide blades are especially useful for industries requiring precise and delicate cuts, such as fabricating electronics and medical devices.

Achieving clean and accurate cuts guarantees consistency in the manufacturing process, lowers material waste, and improves the quality of the final goods. This precision is essential in applications where even a tiny variation from specifications might have significant repercussions.

Enhanced Efficiency and Productivity:

Enhanced productivity and efficiency in industrial processes are directly linked to the durable nature of industrial carbide blades and knives. Without sacrificing performance, these blades can handle heavy-duty applications and high-speed cutting.

Cutting operations may be carried out more quickly and effectively because of the precision and durability combined. Production line optimization is aided by the increased throughput, shorter processing times, and general efficiency these sectors enjoy.

Long-Term Cost-Effective Solutions

Industrial carbide blades may initially cost more than standard steel blades, but over time, carbide blades prove to be more cost-effective. These blades have a longer lifespan, saving on maintenance and replacements over time and lowering overall operating expenses.

For industries that place a high value on cost-cutting without sacrificing performance, industrial carbide blades are a wise investment that will eventually pay for itself in lower total cost of ownership and better efficiency.

To sum up, Industrial carbide blades are indispensable in modern manufacturing processes. Choosing a reliable manufacturer like BAUCOR ensures top-quality products and exceptional customer service experience. With their expertise in crafting custom solutions for diverse industries, BAUCOR continues to lead the way as a trusted provider of industrial carbide blades and knives worldwide.

English

English